Jinpeng Classic Projects Review

Time : May 04,2022 PM

Up to now, Jinpeng mining machinery's EPC One-step service has entered more than 60 countries in the world, and the foreign market share has accounted for more than 70% of the company's total sales. Especially in Southeast Asia and African countries, Jinpeng has become a well-known trademark, and Jinpeng Group has become a famous enterprise rising to the world

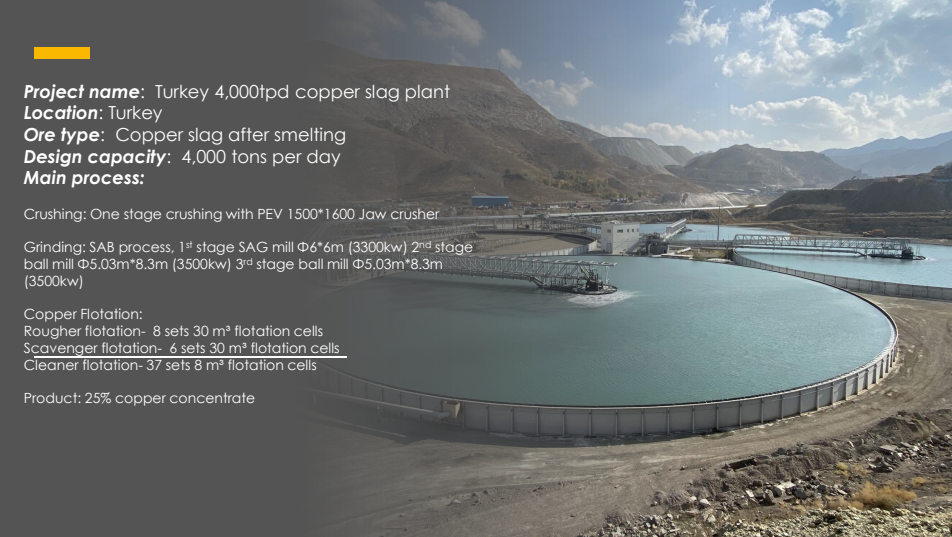

Location: Turkey

Ore type: Copper slag after smelting

Design capacity: 4,000 tons per day

Location: Armenia

Ore type: Copper sulphide ore

Design capacity: 2,000,000 tons per annual

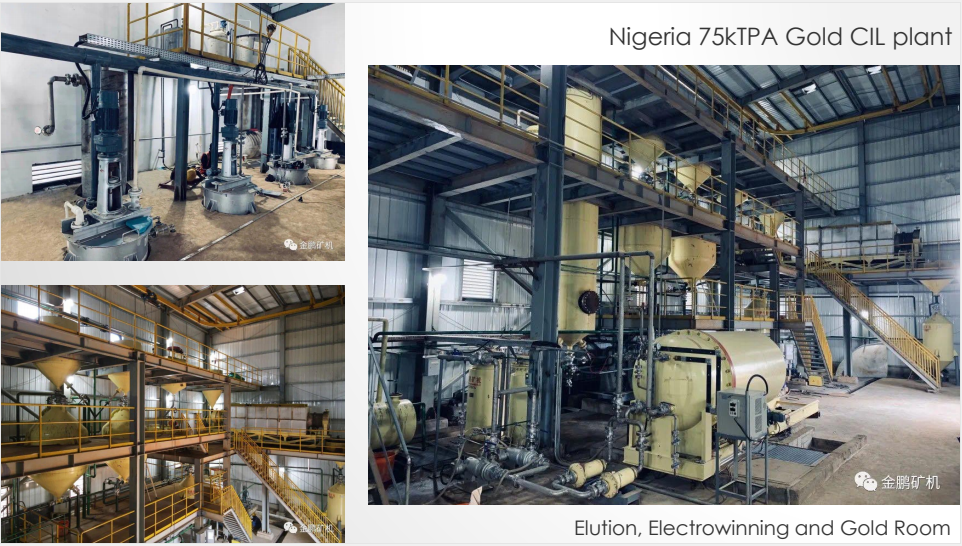

Location: Nigeria

Ore type: Oxide Gold Ore

Design capacity: 750,000 TPA

Location: Zambia, Africa

Ore type: Oxide & sulfide copper ore

Design capacity: 110tph

Location: China

Ore type: Lead and Zinc

Design capacity: 12,000 tons per day

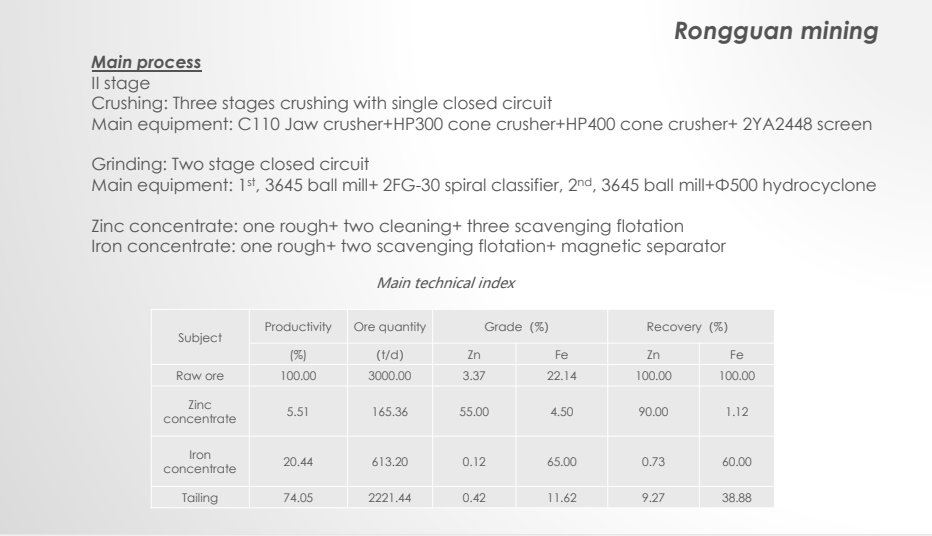

Location: 180km from Dongwuzhumuqin banner, Inner Mongolia, 45°59′49″N, 118°17′50″E

Ore type: Iron and zinc

Design capacity: I stage 500,000 TPA+ II stage 1,000,000 TPA

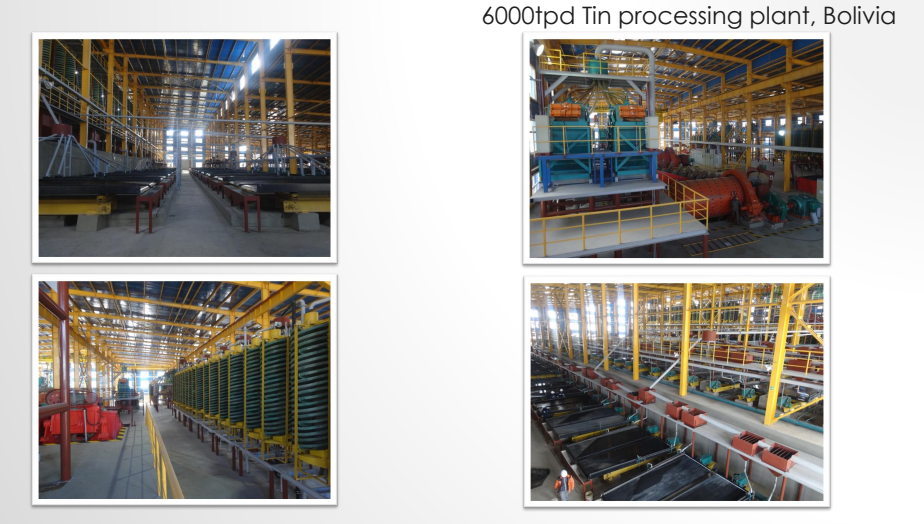

6000tpd Tin processing plant, Bolivia

Raw ore grade:2-3%,

Recovery:92%

Location: East province, Mongolia

Ore type: Lead and zinc

Design capacity: 1,000,000 TPA

Location: Keshiketeng banner, Inner Mongolia, 43°00′15″N, 117°42′30″E

Ore type: Molybdenum ore

Design capacity: 2,000,000 TPA

Main process

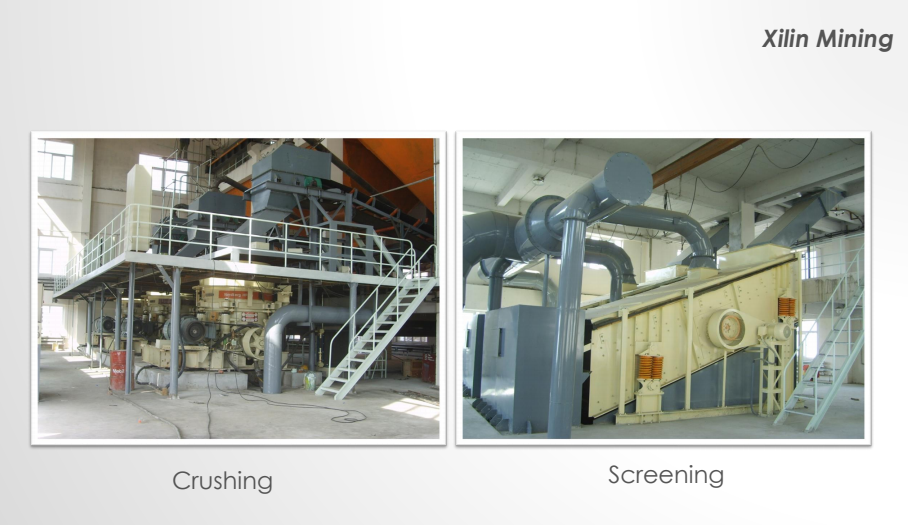

Crushing: Three stage crushing with single circuit

Main equipment: C125 Jaw crusher+HP400 cone crusher+HP400 cone crusher+2YA2460 screen

Grinding: Three parallel one stage closed circuit

Main equipment: 3645 ball mill+ 2FG-30 spiral classifier

Molybdenum flotation: One rough+ four cleaning+ three scavenging flotation

Main equipment: 16m³ floatation machine, 3m³ floatation machine

Final product after thickening and filtration:51% Molybdenum concentrate, moisture≤9%.

Location: 147km from Wulateqian banner, Inner Mongolia

Ore type: Gold ore

Design capacity: 330,000 TPA

Main process

Crushing: Three stage crushing with single closed circuit stage

Main equipment: C24x36Jaw crusher+S115B cone crusher+S115D cone crusher+YAHG2448 screen

Grinding: Two stage grinding with two closed circuits

Main equipment: 1st , 2436 ball mill+ FG-20 spiral classifier, 2nd , 2136 ball mill+ Φ250x4 hydrocyclone

Cyanide leaching& Adsorption: CIL

Main equipment: Φ6m*6.5m double impeller agitation tank

Tailing: Pressure filtration and dry heaping process, moisture of tailing cake ≤18%

Main equipment: XMZ800/2000 chamber type filter press

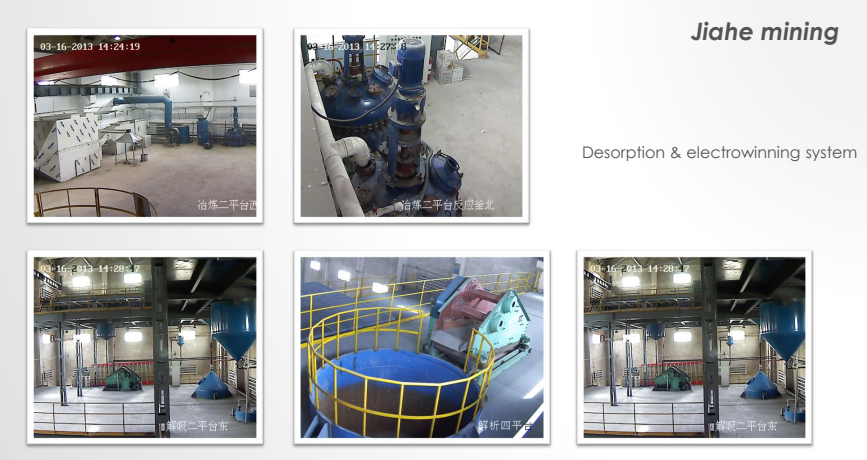

Desorption & electrowinning system: 1000kg/batch

Smelting: Hydrometallurgy+ high frequency furnace ingoting

Final product: ≥ 99.5% gold ingot

Thousands of projects

Typical projects over the world

Our service got good repution in Canada, Germany, Australia, Fiji, Turkey, Albania, Brazil, Zimbabwe, Ghana, Zambia, Tanzania, Morocco, Nigeria, Malaysia, Philippines, India, Vietnam, Myanmar, Laos, Cambodia, Mongolia, Ecuador, Peru, Bolivia, etc, more than sixty countries.

You can share this product to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский