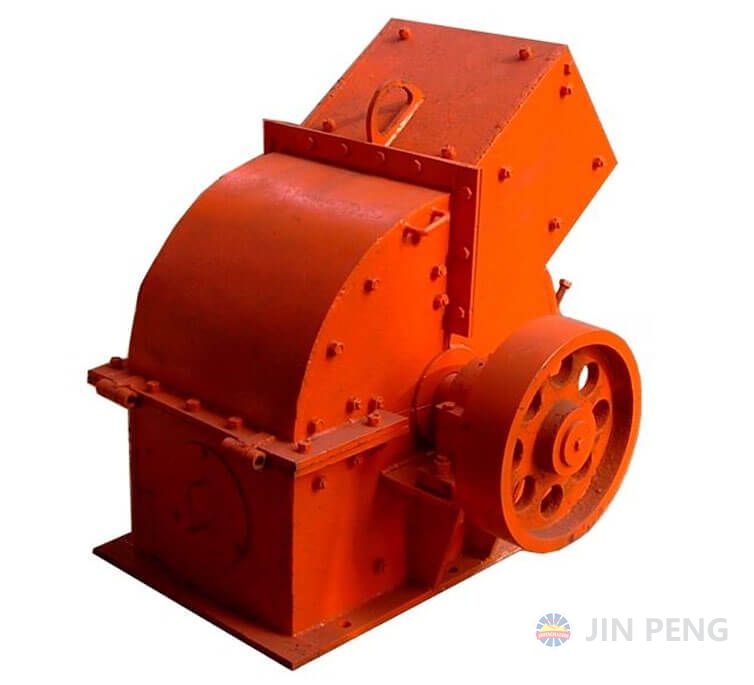

Hammer crusher

Hammer crusher is mainly used in medium crushing process, its structure is relatively simple, mainly composed of the engine body, head, the rotor with ring hammer, sieve, sieve plate adjustment device, etc.

Production capacity:5-150m³/h

Application material:Limestone, slag, coke, coal, salt, chalk, plaster, alum, iron ore, non-ferrous metal ore, etc

Structure

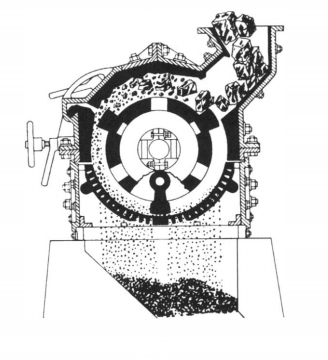

Hammer crusher is mainly used in medium crushing process, its structure is relatively simple, mainly composed of the engine body, head, the rotor with ring hammer, sieve, sieve plate adjustment device, etc.Motor to drive the rotor directly by elastic coupling in the studio.Rotor is consist of the spindle, end plate, ring hammer parts. Motor drives the rotor high-speed revolution then reach the role of crushing material. The engine body is made up of upper and lower casing, crushing plate, sieve plate, etc. Crushing plate and sieve plate is installed on the plate.Lining plates are installed on the wall on either side of the chassis, can prevent casing wear. Crushing cavity is composed of crushing plate, screen plate, back plate and rotor and worm, turbine, pointer and other components compose the adjustment device.

Principle

Motor drives the rotor high-speed rotation in the crushing cavity , the material from the upper feeding mouth to into the machine, the high-speed movement of the hammer blow,the materials become comminution by impacting, shearing, grinding and crushing. There are sieve plate at the bottom of the rotor,comminuted material less than the screen hole size are discharged through the sieve plate, and the coarse material greater than the screen hole size continued being hit by the hammer on the sieve plate and grinding, and finally through the sieve plate outside.

product advantage

Crushing ratio (generally 10 to 25, the most up to 50), high production capacity, uniform product , over crushing less, low energy consumption per unit product, simple structure, equipment quality light, easy in operation and maintenance.

Parameters

Hammer mill | ||||

Model | Max particle(mm) | Output Adjustment Range(mm) | Capacity(t/h) | Power(KW) |

PC-375*300 | 100 | 3-15 | 1.5 | 5.5 |

PC-600*400 | 100 | 10-35 | 7-15 | 18.5 |

PC-800*600 | 200 | 10-35 | 15-26 | 45 |

New type Hammer mill | ||||||

Model | Feeding pressure | Max particle(mm) | Output Adjustment Range(mm) | Capacity(t/h) | Dynamo Model | Dynamo Power |

PCA-800*800 | 800*800 | 350 | 20-60 | 30-60 | Y-225S-37KW-4 | 37 |

PCA-800*1000 | 800*1000 | 400 | 20-60 | 50-80 | Y-250S-55KW-4 | 55 |

PCA-800*1200 | 800*1200 | 400 | 20-60 | 70-90 | Y-280S-75KW-4 | 75 |

PCA-800*1800 | 800*1800 | 400 | 20-60 | 90-120 | Y-315S-110KW-4 | 110 |

PCA-1000*1000 | 1000*1000 | 500 | 20-80 | 70-100 | Y-280S-75KW-4 | 75 |

PCA-1000*1250 | 1000*1250 | 500 | 20-80 | 80-120 | Y-280S-90KW-4 | 90 |

PCA-1000*1500 | 1000*1500 | 500 | 20-80 | 120-160 | Y-315S-110KW-4 | 110 |

PCA-1250*1500 | 1250*1500 | 600 | 20-100 | 140-180 | Y-315S-132KW-4 | 132 |

PCA-1250*2000 | 1250*2000 | 600 | 20-100 | 160-220 | Y-315S-160KW-4 | 160 |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский