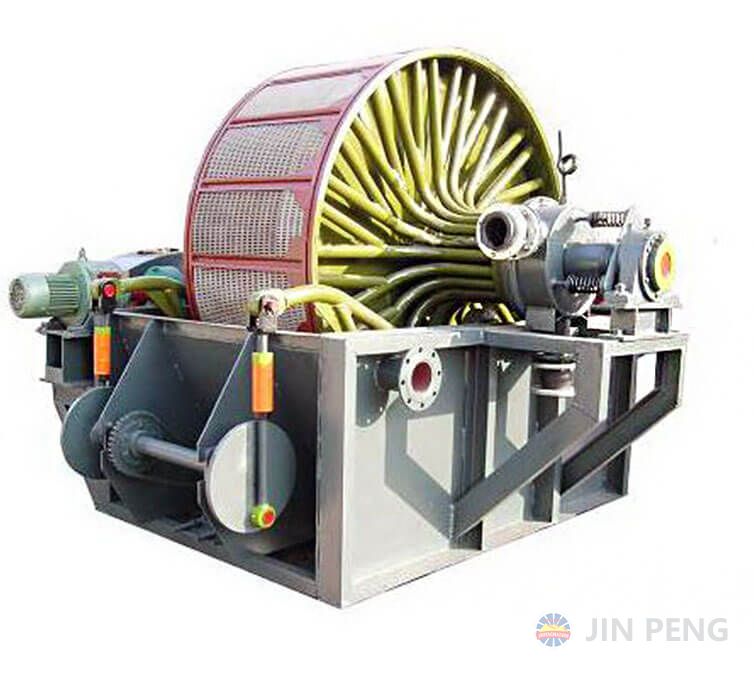

Permanent magnetic Vaccum filter press

It is an ordinary type filter which has super speed by adjusting motor. It has the advantages of simple structure, low price, convenient use, less maintenance and less wearing.

Production capacity:0.68-8 t/h

Scope of Application:Ore dressing, metallurgy, chemical industry, papermaking and other departments

Structure

The inside of the cylinder is installed with a strontium ferrite permanent magnetic system. The system can make the magnetic particles rapidly be adsorbed to the filter surface.

The magnetic filter is mainly used for the dehydration of coarse-grained strong magnetic minerals concentrate slurry.

Because of the upper feeding, the effect of concentrate granularity stratification in the filter cake is more obvious.

When the magnetic concentrate forms the filter cake, the particles are affected by the action of gravity and magnetic force. The movement speed of coarse concentrate to the cloth is faster than that of fine particles concentrate. So the concentrate particles contact the filter cloth first and the filter cake’s permeability is good.

Under the effect of magnetic attraction, the magnetic particles in the slurry distribute in radial shape on cylinder’s surface. The change of polarity magnetic system has a magnetic stirring effect. These become the favorable conditions of filter cake easy to dehydrate, and make the cake thick and have good air permeability.

So the productivity has been raised greatly. Compared with the same specifications cylinder vacuum filter, the efficiency is increased by more than three times.

Advantages

Better Granular Scalability, better air permeability of the filter cake;

With magnetic stirring function, it benefits for dewatering work;

Higher productivity, lower operation cost.

Parameters

| Vaccum permanent magnet filter | ||||||||||

model | filter area(m²) | barrel specification (mm) | barrel speed (r/min) | Tube sheet of magnetic induction intensity | vacuum pressure(kpa) | swept volume(m³/min.m²) | Blast indicated pressure (kpa) | Production capacity(t/h) | motor power(KW) | weight (T) |

SGYW-3 | 3 | Φ1600×700 | 0.5-2 | 82 | 60-80 | 0.5-2 | 42673 | 42530 | 1.5 | 3.3 |

SGYW-5 | 5 | Φ2000×900 | 0.5-2 | 82 | 60-80 | 0.5-2 | 42673 | 14-18 | 1.5 | 3.9 |

SGYW-8 | 8 | Φ2000×1400 | 0.5-2 | 82 | 60-80 | 0.5-2 | 42673 | 22-43 | 1.5 | 4.8 |

SGYW-12 | 12 | Φ2000×2000 | 0.5-2 | 87 | 60-80 | 0.5-2 | 42673 | 33-65 | 2.2 | 5.4 |

SGYW-20 | 20 | Φ2550×2650 | 0.5-2 | 87 | 60-80 | 0.5-2 | 42673 | 50-100 | 4 | 6.5 |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский