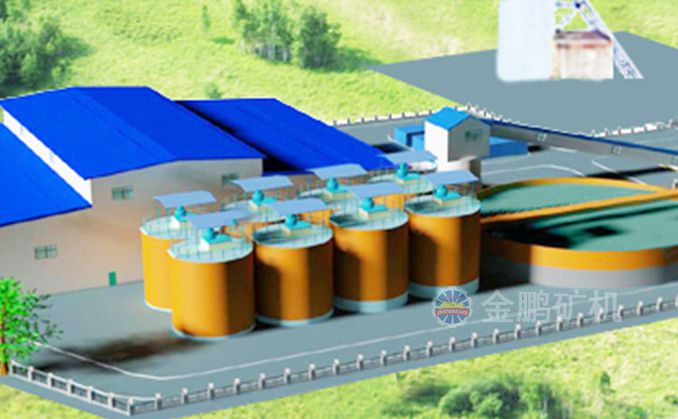

Guatemala 300 t/d CIL plant

Guatemala customers personally visited jinpeng factory, and highly praised the quipment manufacturing level.After that, we signed the contract without any hesitation. The project is 300 t/d CIL project, as the best supplier and service company for gold ore dressing, we have provided the professional guidance to our customer. At present,the project equipment has been made completely, jinpeng engineers are on-site installation.

Capacity:300t/d

Finished time:Under construction

Location:Guatemala

Project Process

Flowsheet

1.Feeder and screen system

Ore shipped by truck to the raw ore bin, ore bin are installed on the grizzly, oversize material by hydraulic hammer artificial broken, under size to 1 # belt conveyor into the vibrating screen for screening, oversize to 2 # belt conveyor to return to the second period of fineness crusher, forming a closed-circuit crushing process.Under size ore go through the 3 # belt conveyor to the steel structure fine ore bin.

2.Grinding classification system

Powder ore from fine ore bin via belt feeder to 4 # belt conveyor and transport to energy-saving ball mill, by slurry pump go to the hydro cyclone classification,cyclone under flow return to ball mill for grinding, the overflow enters into the thickener after removing impurity

3.Thickener and leaching system

Pulp with efficient modification thickener concentration, overflow water flow into the circulation pool, bottom pulp through the rubber pump to the leaching tank, at the same time, putting the leaching reagents,after two primary leaching tanks, for activated carbon adsorption, we put the activated carbon from the end leaching tank, gradually countercurrent bunch of carbon to the front of the leaching tank, when the gold achieved requirement,by using the air lifter to the vibrating screen, pulp back to the leaching tank, sent loaded carbon to the desorption electrolysis system.

4. Desorption electrolysis system

After washing the loaded carbon in the carbon storage tank,we put the desorption liquid from the bottom of desoprtion column,which will carry the gold cyanide complex desorption down ,after filter to get gold mud into the cell electrolysis

5.Dosing system

There are a lot of doing points in the CIL plant,in order to guarantee the continuous of the dosing accuracy,we use our own patent technology touch-screen computer dosing machine to control each point of dosing, and supporting agent stirring and mixing with lime.

6.Dehydration system

The tailing from the last leaching tank will go to the fully automatic box-type pressure filter, the water into the circulation tank for recycling, and filter cake by belt conveyor to the tailing yard, truck can be used to take these cake to the tailing dam.

Manufacturing

We have a very strict management for each project, and one people will be responsible for each project from the beginning to the end,which can make sure the whole process smoothly.

Design institute will start from engineering design, precise positioning technology and its products, not only guarantee the technology, but also reduce customer cost and choose the best process.

At the same time, we have a very strict quality management for equipment production,and have passed the ISO 9001:2008 international quality certification. Several large automatic CNC cutting machine, CNC automatic welding machine, 5 meters CNC vertical lathe, CNC lathe, CNC boring machine, and has the longest 15 meters large lathe in Shandong, all of this can guarantee the accuracy of the equipment and the appearance of fine quality.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский