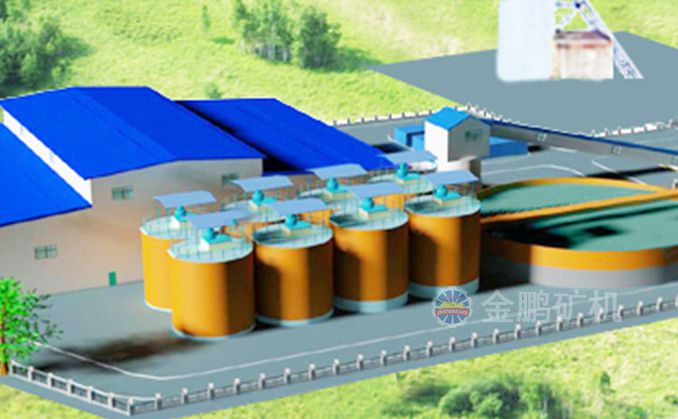

Peru's 200 t/d polymetallic ore flotation plant

This project is located in Qinbote, Peru, authorized by the customer, from engineering consulting, beneficiation test research, the design of the plant, mining equipment, equipment manufacturing, installation and debugging to the worker training, to perform the entire process all by jinpeng group, finally selected the gold flotation process.The project started in 2011,and completed put into operation in 2012, benefit is very good.

Capacity:200t/d

Finish Time:2012年

Location:Chimbote

Project Process

The flotation plant is processing outside mines, crushing system uses two section of one closed-circuit two grinding flotation series, grinding system uses a closed-circuit grinding ball mill + hydrocyclone ,flotation process is very flexibility, can deal with gold, silver, copper, lead and zinc single mineral, can also be processing polymetallic mines.

Flowchart for gold flotation

Flotation processing is one of the most widely dressing method for gold mine, often used for handling the flotability high sulfide minerals .Flotation process can match the gold enrichment to maximize the sulfide minerals, the tailing can be directly discarded, low processing cost, 80% of rock gold deposits in China are using this technology.

Flotation process including dosing, mixing, inflatable, blow a bubble and so on.

Main influence factors including grinding fineness, pulp density, reagent dosage, air inflatable, flotation time, etc.Usually, these process conditions require beneficiation test and practical experience to determine.

Application Field

Gold flotation technology is suitable for processing gold grains finer, good flotability of gold-bearing sulfide ore, in the process of flotation, sulfide ore as the carrier of gold was enriched in sulfide concentrate, flotation process can also be used to process the polymetallic gold sulfide ore and carbonaceous ores, etc.In addition, for "hard look" ore , also need to be used flotation process for processing.

Manufacturing

We have a very strict management for each project, and one people will be responsible for each project from the beginning to the end,which can make sure the whole process smoothly.

Design institute will start from engineering design, precise positioning technology and its products, not only guarantee the technology, but also reduce customer cost and choose the best process.

At the same time, we have a very strict quality management for equipment production,and have passed the ISO 9001:2008 international quality certification. Several large automatic CNC cutting machine, CNC automatic welding machine, 5 meters CNC vertical lathe, CNC lathe, CNC boring machine, and has the longest 15 meters large lathe in Shandong, all of this can guarantee the accuracy of the equipment and the appearance of fine quality.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский