Sudan RIDA mining 1500t/d CIL plant

It is a EPC project. Jinpeng supplied one package service, include engineering consultation, mineral processing experiments, engineering design, equipment manufacture, installation and commissioning, personal training.

Capacity:1500t/d

Finished time:2014.8

Location:Sudan

Introduction

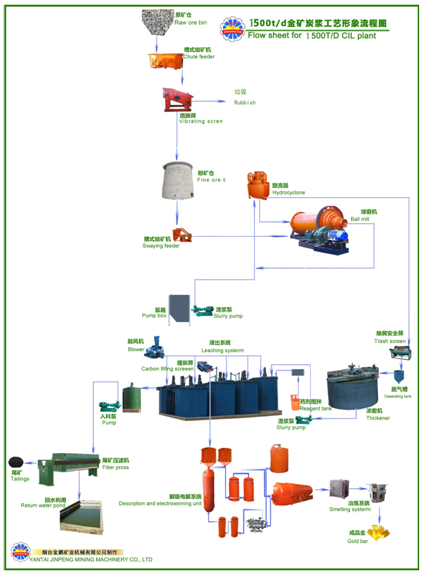

process

CIL process is mainly include : decontaminate , concentrate before leaching , leaching and adsorption , desorption and electrowinning , hydrometallurgy , regeneration of activated carbon , tailings filting , waste water treatement and so on .

1、Decontaminate impurity :remove the impurity like the bits of mood before cyanide adsorption , avoid the bits of mood adsorb the gold from slurry , avoid the bits of mood block the carbon separator .

2、Concentrate before leaching , usually to reach a suitable leaching concentrate , the slurry should be dewatered through the thickener before leaching , the concentration could influence the leaching time and influence the float of activated carbon .

3、Leaching and adsorption : put the slurry after decontaminated and concentrated into the high-efficiency leaching tank , there are 5-8 tanks normally , add cyanide solution into the former two tanks , add activated carbon into the other five tanks , activated carbon adsorb gold become the loaded gold carbon , the loaded gold carbon lift into the lifting screen by air lifter , the lifting screen separate activated carbon and slurry .

4、Desorption and electrowinning : the desorption of activated carbon and electrowinning the liquid gold are completed in a closed system , in a high temperature and high pressure , activated gold carbon after desorption and electrowinning become gold pulp and barren carbon . Main equipment including : desorption column , acide tank , heater , filter , desorption tank , electrowinning tank and so on .

5、Smelting : after acide washing and decontaminate , gold ingot will be smelted . With the method of hydrometallurgy , the gold grade could be 99.99%.

6、Application of the regenerated activated carbon : the activated carbon after desorption make acide washing to remove the carbonate accumulate , after times of using that need heating activated to regenerate the carbon , then for recycling . Main equipment including activated carbon regenerated tank , water quench tank , fine carbon separate screen .

project site

Manufacturing

We have a very strict management for each project, and one people will be responsible for each project from the beginning to the end,which can make sure the whole process smoothly.

Design institute will start from engineering design, precise positioning technology and its products, not only guarantee the technology, but also reduce customer cost and choose the best process.

At the same time, we have a very strict quality management for equipment production,and have passed the ISO 9001:2008 international quality certification. Several large automatic CNC cutting machine, CNC automatic welding machine, 5 meters CNC vertical lathe, CNC lathe, CNC boring machine, and has the longest 15 meters large lathe in Shandong, all of this can guarantee the accuracy of the equipment and the appearance of fine quality.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский