Antimony ore processing

Antimony ore proportion is heavy than matrix , normally gravity separation is more efficient , its efficiency , economic , environment protection and concentrate the lower grade ore , after gravity use flotation for extraction .

Introduction

Generally , the separation process including manual , gravity , flotation separation , most of the time , use unite processes . No matter oxide ore or sulfide ore , they all heavier than matrix , so we could choose gravity separation for most of the antimony ore . For the ore with thick grain , manual separation is more useful .

Gravity separation

Gravity separation divides into heavy medium separation , jig separation , sluice separation and shaking table separation .

Flotation process

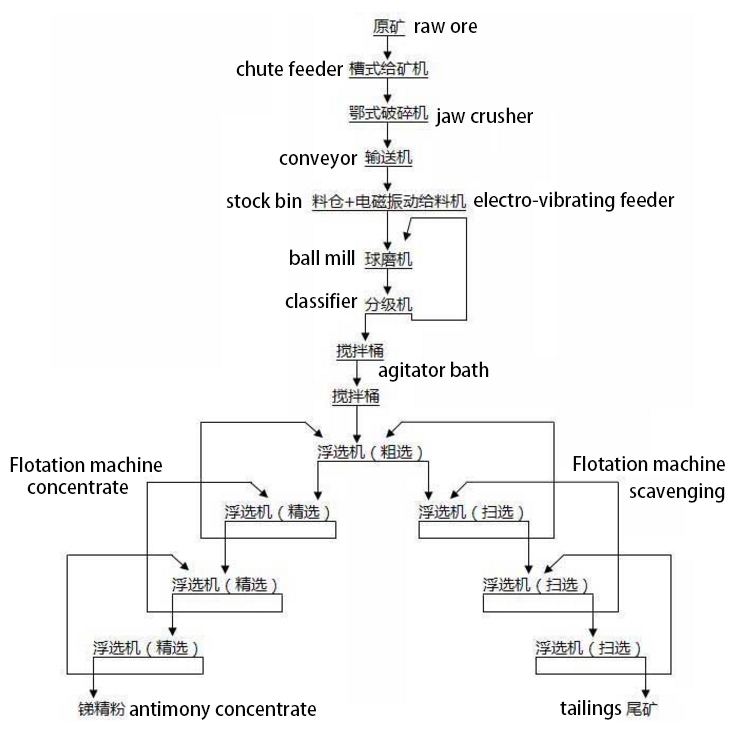

After grinding and flotation the tailings from the gravity separation , use one rough , three concentrate , two scavenging process .

After flotation is the antimony concentrate . The tailings introduced to shaking table , and recover the fine oxide antimony , obtain the high grade antimony concentration and tailings .

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский