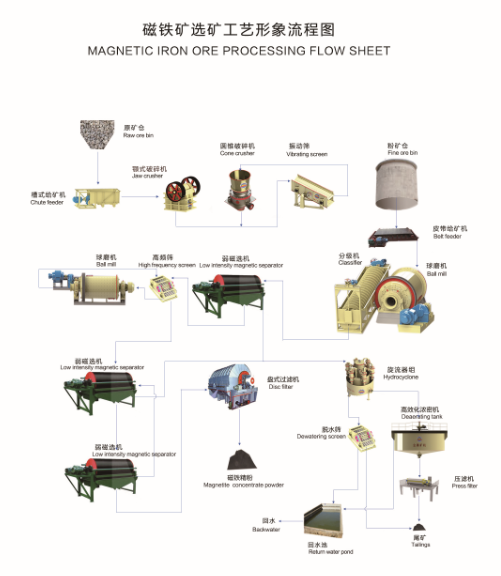

Magnetite Separation Production Line

Compared to other minerals , magnetite ore is easier to separate . We use normally permanent magnetic separator , magnetic pulley and magnetic dewatering tank ,these process are very easy . These years , with the enhance of requirement of fine particles and smelting industry , accelerated the magnetic technology , including the fine screen ,magnetic column and weak magnetic separator --- reverse flotation , that increased the iron grade to 68.85% , silicon decreased to 4% .

Introduction

Application

Magnetite Separation Production Line is used to single magnetite with simple ore properties.

Process introduction

Weak magnetic – reverse flotation process : it`s a process that divides into weak magnetic – positive ion reverse flotation process and weak magnetic –negative ion reverse flotation process , the difference is the reagent , negative ion advantage is that the float is not paste , index stable . Negative ion flotation has high temperature requirement , has bad influence on the pipe of concentrates , need to add acid before filter.

![]()

(Tips: You can add this webpage as favourite, or find it by serach in Google with the keywords below:

Iron ore production line, beneficiation of iron ore, iron ore processing, iron extraction from ore, iron ore beneficiation technology, and so on.)

Related case

Guilin 1500t/d limonite project Laizhou 3000t/d iron ore beneficiation plant

Hanwang Group 2000000t/a iron ore project Huaibei 1600000t/a iron Tailings filling

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский