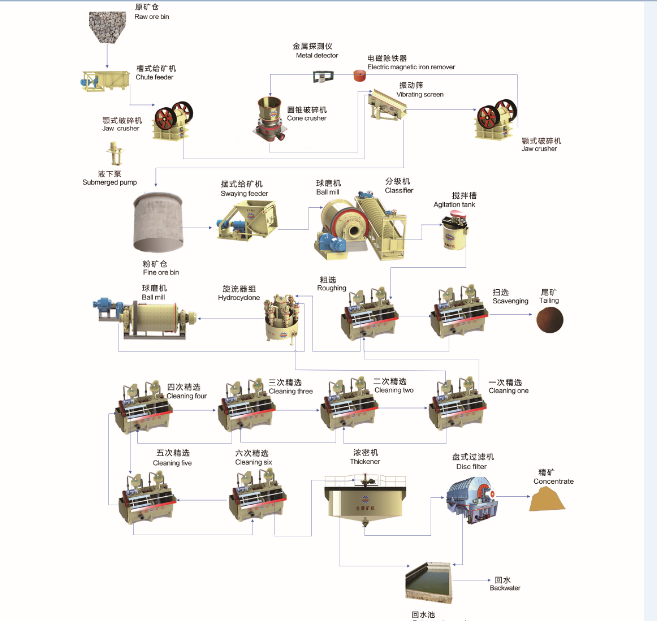

Fluorite flotation process

The beneficiation of fluorite ore is gravity separation and flotation process. The specificity of fluorite flotation: 1. Because industrial making hydrofluoric acid require calcium fluorite content>98% and silica <1%, fluorite flotation generally use 5-7 stages concentration; 2. When the PH of ore pulp is 8-11, the floatability is good. Another, increasing the temperature of ore pulp can improve flotation index.

Introduction

Application

Fluorite flotation process is suitable for high silt content, impurities mineral and fluorite symbiose, fine disseminated grain-size, etc complex ore property and difficult separation fluorite ore.

Process introduction

1. Separation of fluorite and sulphide ore: generally, use xanthate collector to emerge sulphide ore, then add fatty acid collector to float fluorite. Another, during flotation processing, add little sulphite inhibitor to guarantee the quality of concentrated fluorite.

2. Separation of fluorite and barite: Generally, use bulk flotation and then separate. During bulk flotation, use oleic acid as collector to get bulk concentrate. The separation of bulk concentrate can use direct flotation or reverse flotation to get concentrated fluorite.

3. Separation of fluorite and quartz: Use fatty acid to collect fluorite and use water glass to restrain quartz. The dosage of water glass should be proper, little dosage have activation for fluorite ore, but is not enough to control quartz. Over dosage will control fluorite ore. Sometimes, to increase the inhibiting effect, it will add some polyvalent metal ion and it will also control calcite.

(Tips: You can add this webpage as favourite, or find it by serach in Google with the keywords below: fluorite processing, fluorite flotation, and so on.)

Related cases

外蒙1000t/d萤石矿 外蒙 1000t/d萤石矿

陕西延长石油500t/d萤石选厂 锦州500t/d萤石矿

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский