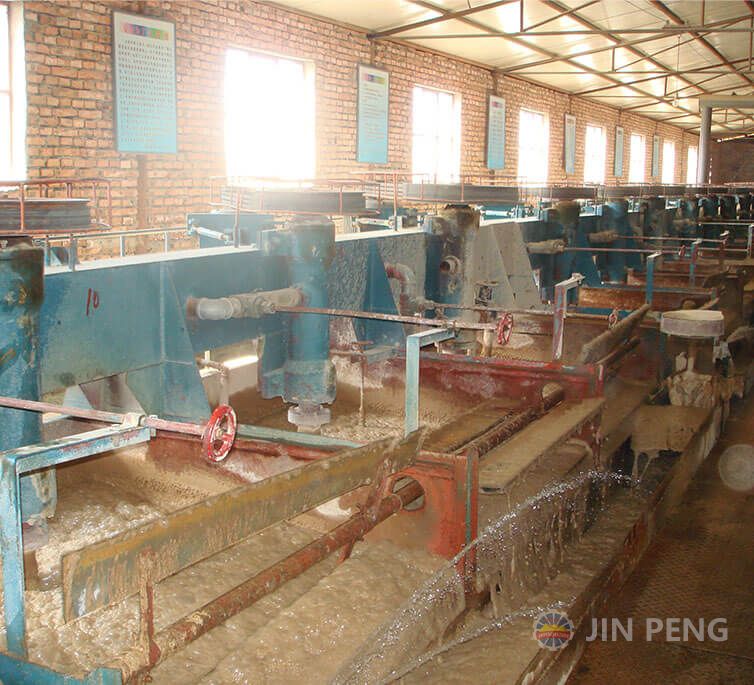

Scheelite flotation process

Scheelite dressing can use gravity, magnetic and flotation separation. The types and properties of the ore decide the separation methods and processes. Basing on good floatability of scheelite, the flotation is selected.

应用领域:白钨矿浮选生产线可适用于矿石中含有多种其他金属矿物及非金属矿物,有用矿物与脉石矿物共生紧密,结构复杂的白钨矿。

Introduction

Scheelite flotation product line is suitable for the scheelite containing multi metals with complex structure.

Separation of scheelite and calcspar & fluorite

Concentration pulp with high temperature is common method. First, the pulp is concentrated to 60%-70%; the next, sodium silicate is added into pulp; then, the pulp is heated to 80℃ and stirred for 30-60min; the last, it is diluted with water. The floatation of scheelite is under the room temperature, and the product in tank is calcspar & fluorite.

The separation of scheelite and barite

It is difficult to separate scheelite and barite by sodium silicate because of the closed inhibitory action for scheelite and barite. We choose alkyl sulfate as collector to repeatly select barite under the 1.5-3PH, and the product in tank is scheelite.

The separation of scheelite and sulfide

Xanthate is used to capture sulfide minerals in scheelite floatation. We add a little oxide and sodium sulfide to inhibit sulfide without floatation.

The separation of scheelite and Quartz silicate

Oleic acid as collector and sodium silicate as inhibitors, which could inhibit the quartz and silicate gangue and float scheelite.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский