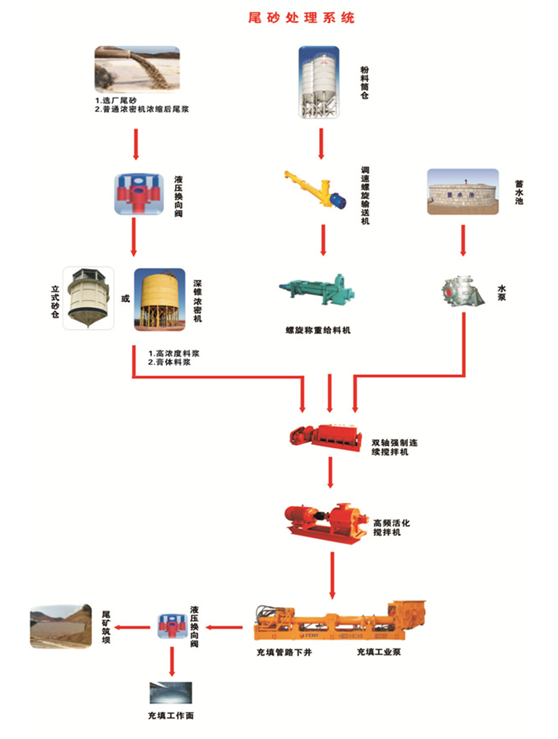

Whole tailings cemented fill process flowsheet

• Whole tailings cemented fill process, based on physical chemistry and colloid chemistry, directly use the tailings, dewater by thickener and sand silo setting, mix the whole tailings and certain proportion cement into homogeneous cemented fill material by biaxial blade type mixer and high speed activating mixer.

Introduction

Application: all kinds of tailings process.

Process introduction

This system is made up by dewatering system, agitating system, piping transporting system, automatic detection and adjustment system. Tailings pulp are conveyed to agitator after dewatering by deep-cone thickener and vertical sand silo. In agitator, add water and cement and mix to make high concentration pulp. Then feed into activating mixer to improve the workability. Then use the filling industry pump and pressure pump through piping to convey the pulp to underground gob.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский