Nickel Ore processing

Nickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process .

Introduction

Application

many kinds of copper nickel ore or nickel oxide ore with pyrite and other minerals .

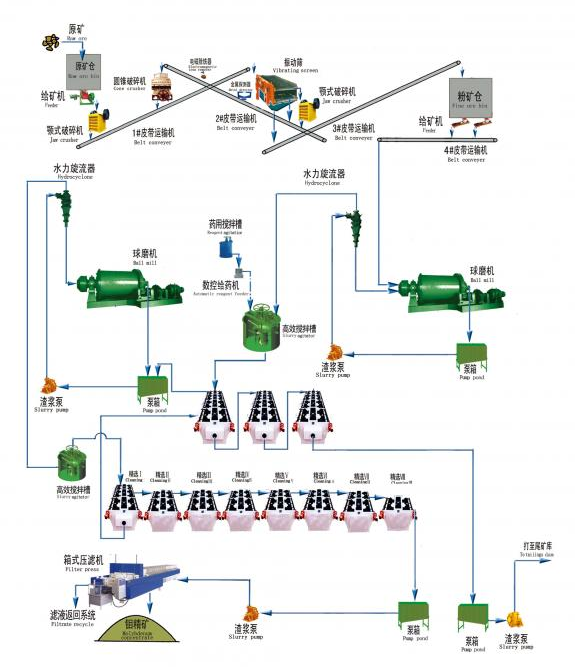

Process

1. Mix flotation process

For separation of the ore that copper grade lower than nickel , the concentrate with copper and nickel will be smelted into high-grade nickel matte

2. Mix – flotation process priority

mix-flotation the copper nickel from the ore , then separate the low grade nickel and low grade copper concentrate from the mix concentration . The nickel concentrate after smelting obtain the high-grade nickel matte , then use floation to separate the high-grade nickel matte .

3. mix-priority flotation and recovery the nickel from tailings

When the variety of nickel minerals are more floatable in the ore , after floation , recover the nickel minerals that less floatable in the tailings .

4. Copper nickel ore flotation process:

Use collector and foaming agent in the flotation of nickel ore with copper sulfide . The principle for determine the flotation process is avoid the nickel goes into the copper concentrate as possible . When copper grade is higher than nickel , we could separate copper as copper concentrate . Obtain the copper concentrate that with less nickel is the advantage.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский