Phosphorus ore flotation process

According to different phosphorus ore property, phosphorus ore separating process have flotation, scrubbing desliming, gravity separation, chemical leaching, combined separating, photoelectric selection, magnetic coating, etc. the flotation is most applied, including direct flotation, reverse flotation, direct-reverse flotation and double reverse flotation.

Introduction

Application

Phosphorus ore flotation process is suitable for complex ore texture, complex ore occurrence relationship, fine particle size, disseminated closed, mixed symbiosis, difficult monomer separation phosphorus ore.

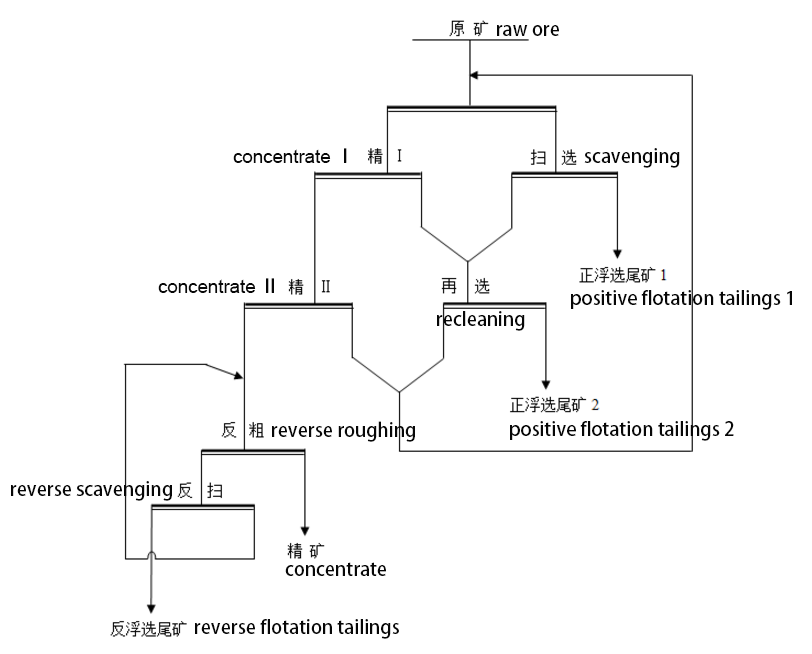

Process flowsheet

1. direct flotation process

Direct flotation use effective inhibitor to control gangue mineral and collector to concentrate phosphorus in foam. It is suitable for low grade phosphorus ore, including magmatic rock type apatite and deposition metamorphic type apatite.

2. reverse flotation process:

Mainly used for separation of phosphorus and dolomite. Use fatty acid collector to emerge dolomite in alkalescence medium and enrich phosphorus in tank. The greatest advantage is flotation in normal temperature and the particle size of product in tank is coarser that is good for subsequent process.

3. double reverse flotation

In alkaline condition, Double reverse flotation let silicate surface take positive charge and use anion collector to separate the ore. Flotine dolomite first, then reverse flotine silicate, the heavy concentrated ore left in tank. This process can be operated under normal temperature and coarse particle size.

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский