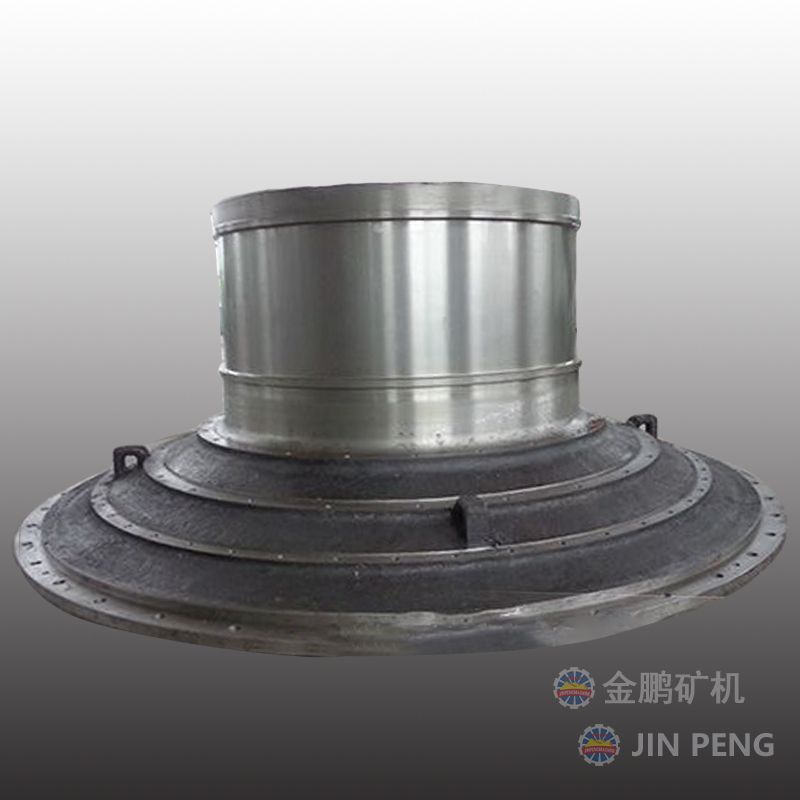

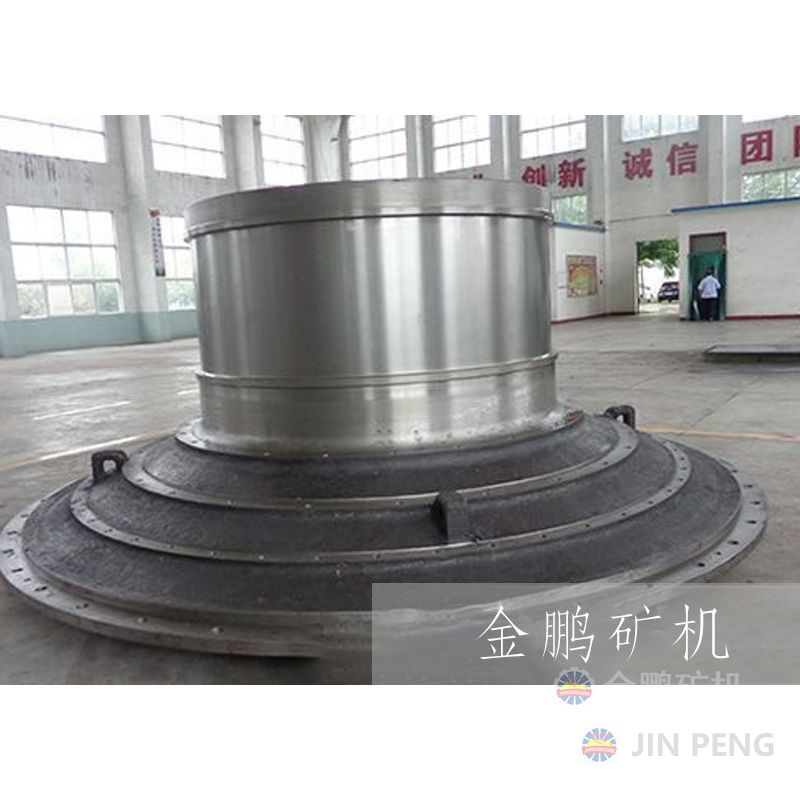

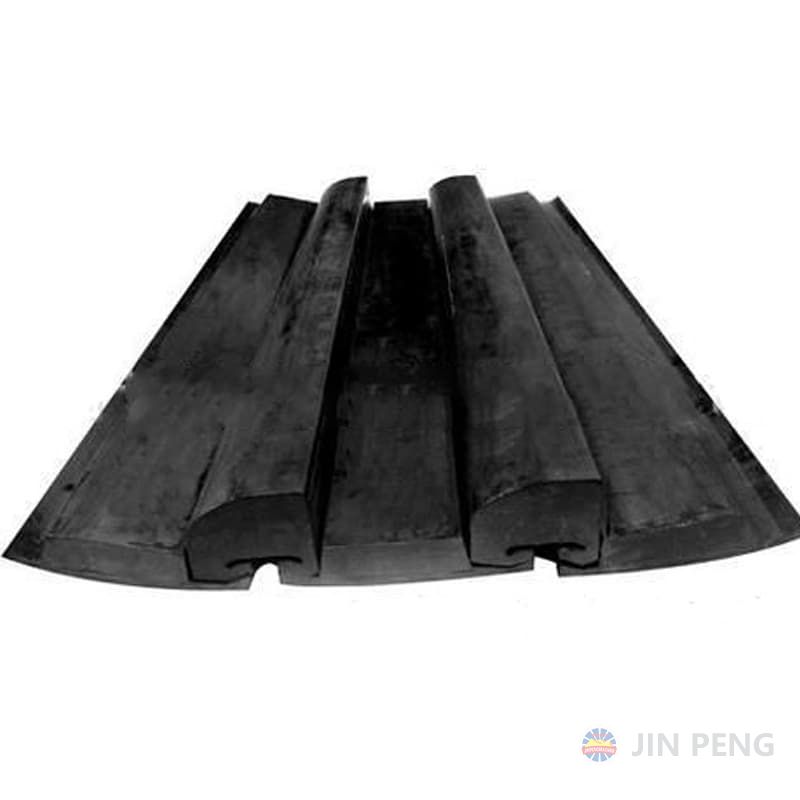

End Cap Cover Casting for Ball Mill

End Cap Cover Casting for Ball Mill

Size: According to drawings

Application: Mining machinery

Product Description

Grinding mill end cap is one of the key part of ball mill, its structure is relatively complex, long production cycle, high precision of processing and assembling, so when compiling process routes, should fully consider its manufacturability.

Application

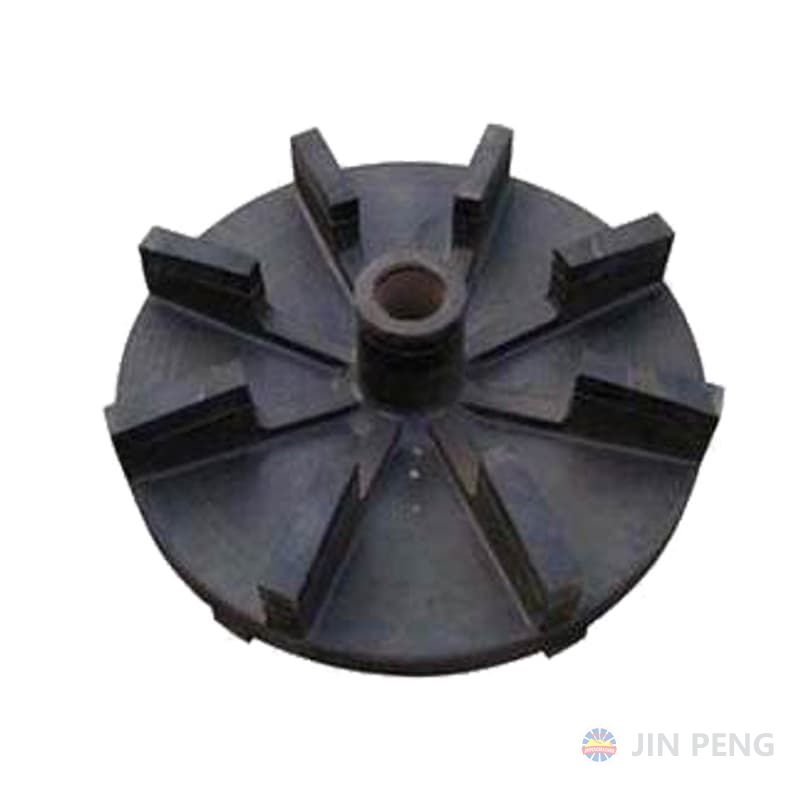

Cement/ Mill and Kilns;Mining and Minerals/Rotary Dryers;Pulp & Paper/ Kilns, Debarking Drums, Drum Pulpers;Chemical / Fertilizer Industry / Food Industry

Material

Carbon steel, alloy steel or according to customer's requirements.

Features

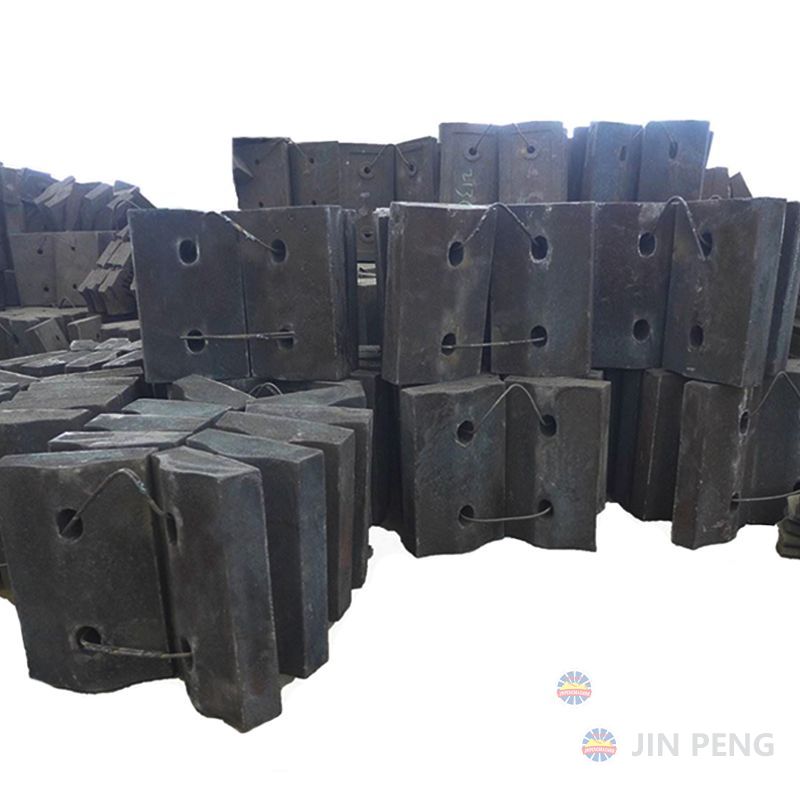

1. Available in different hardness range

2. Can be developed using material choices including Cast steel, Ductile iron, Fabricated forged steel plates and others.

3. As an important component in gear drive assembly, these can be offered in multiple segments including 2, 4 or 8 equal sizes.

4. Easy installation and low operational costs

Product name | Ball mill end cover |

Material | ASTMA-27 |

Structure | Casting |

Process | Lathing, milling, drilling |

Heat treatment | HRC of surface quenching 58-62 |

Certificate | ISO |

Type | According to drawing |

Package | Seaworthy packing |

Delivery time | 30-90 days |

Certification | ISO9001-2008 |

Recommended

Español

Español русский

русский