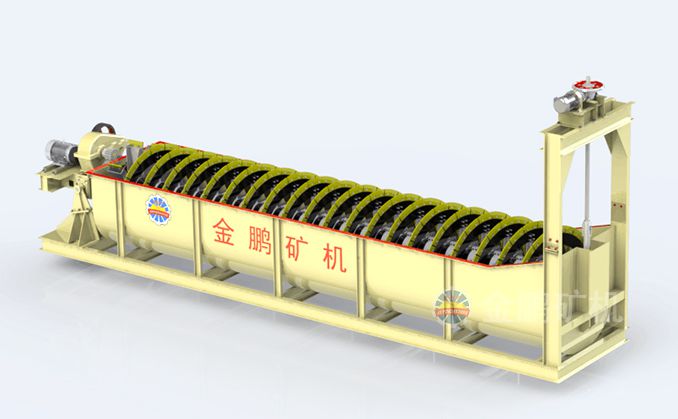

High weir spiral classifier

The single spiral classifier is an up-dated one which is formed by gearing, spiral, cell body and lifting device etc. It increases an automatic sand-return device at the sand-return part. Lift ore sand that discharged at tank bottom to a proper position at tank wall, to adapt the configuration of ball mill cancelled big spoon head.

Scope of Application:Grinding auxiliary equipment for classification and grading inspection in advance, also used to contain clay minerals for washing and desliming, dehydration of pulp.

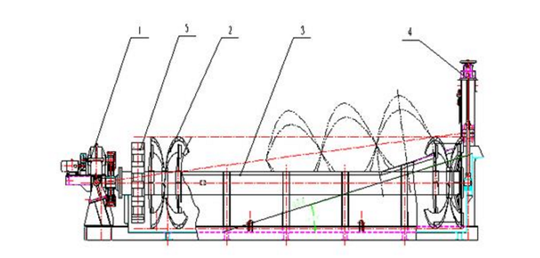

Structure

1. Gearing 2. Spiral 3. Cell 4. Lifting Device 5. Auto sand returning device

Spiral classifier is composed of transmission mechanism, (left, right) spiral water tank, lifting device, lower support, lubricating device, ore discharge valve, feed inlet, etc

The water tank of this machine is installed obliquely. The angle of inclination is determined according to equipment configuration of equipment in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the water tank. The finely grained slurry enters the water bank from the feed inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank’s inclination angle and the height of overflow edge. The spirals rotating at a low speed play a certain stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. Classifiers normally form closed loop operation together with mill.

Advantages

1. Good adaptability

2. Easy maintenance

3. High classifier efficiency

4. Simple and reliable structure

5. High classifier production

6. easy to operate

Parameters

| High weir spiral classifier | |||||||||||

Type | Model | Specification | spiral diameter(mm) | Spiral speed(r/min) | Flume | Production capacity(t/24h) | drive motor power(kw) | lifting motor power(kw) | |||

length(mm) | width(mm) | obliquity(°) | overflow Volume | Sand return Volume | |||||||

single-screw | FG-5 | Φ500 | 500 | 9.2 | 3900 | 560 | 10.5°-14° | 21-75 | 145-260 | 3 | |

FG-7 | Φ750 | 750 | 7.8 | 5367 | 830 | 10.5°-14° | 65-154 | 255-564 | 3 | ||

FG-10 | Φ1000 | 1000 | 7 | 6500 | 1110 | 10.5°-14° | 85 | 473-1026 | 5.5 | ||

FG-12 | Φ1200 | 1200 | 5,6,7 | 6500 | 1372 | 10.5°-14° | 150 | 1145-1600 | 5.5 | 2.2 | |

FG-15 | Φ1500 | 1500 | 2.5,4,6 | 8265 | 1664 | 14°-18.5° | 235 | 1140-2740 | 7.5 | 2.2 | |

FG-20 | Φ2000 | 2000 | 5.4 | 8400 | 2396 | 14.5°-18.5° | 400 | 5940 | 15 | 2.2 | |

FG-24 | Φ2400 | 2400 | 3.6,5.4,6.3 | 9160 | 2600 | 14°-18.5° | 580 | 6800 | 11/15 | 2.2 | |

FG-30 | Φ3000 | 3000 | 3.17 | 12500 | 3200 | 14°-18.5° | 890 | 11650 | 22 | 4 | |

double-screw | 2FG-12 | Φ1200 | 1200 | 5,6,7 | 6500 | 2620 | 14°-10.5° | 300 | 2290-3200 | 5.5X2 | 2.2X2 |

2FG-15 | Φ1500 | 1500 | 2.5,4,6 | 8265 | 3200 | 14°-18.5° | 460 | 2240-5360 | 7.5X2 | 2.2X2 | |

2FG-20 | Φ2000 | 2000 | 5.4 | 8400 | 4296 | 14.5°-18.5° | 800 | 11880 | 15X2 | 2.2X2 | |

2FG-24 | Φ2400 | 2400 | 3.6,5.4,6.3 | 9160 | 5040 | 14°-18.5° | 1160 | 13600 | 11X2/15X2 | 2.2X2 | |

2FG-30 | Φ3000 | 3000 | 3.17 | 12500 | 6300 | 14°-18.5° | 1785 | 23300 | 22X2 | 4X2 | |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский