Jig

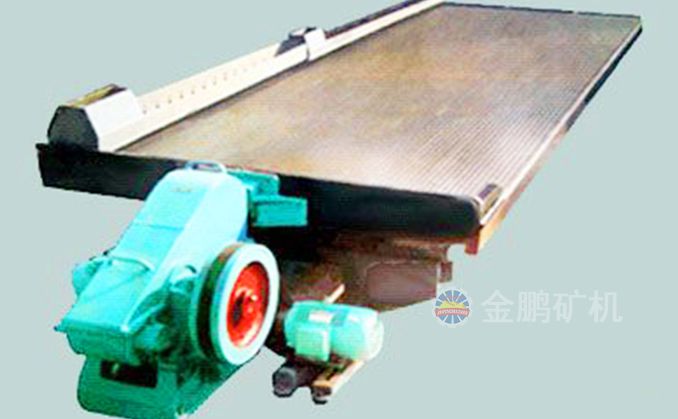

The jig plant (jig machine) belongs to gravity-based equipments, which can separate mineral based on differing of specific gravity. Saw-tooth wave jig mainly consists of three parts: main frame, driving set and jigging chamber.

Production capacity:1~25t/h

Scope of Application:metal ore, such as tungsten, gold placer, etc

Structure

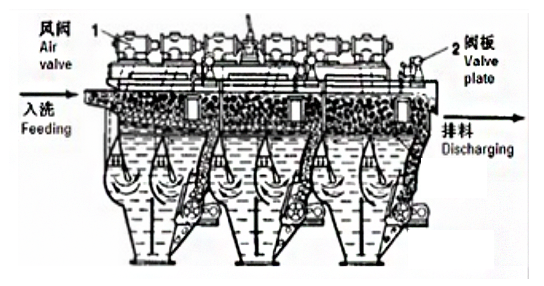

jig plant( jig machine) need water to work, and it loosens materials in vertical alternative water-flows, and it forms different layers of materials of different densities and discharges both layers from up and down discharging ports separately.

The basic composition of jigger is jigging chambers, there have screens in each chamber.Water and raw ore will be fed from one end of the jigger screen, the ore granules will move in the vertical alternative water-flows. Layers will be formed because of density difference of materials. The minerals with small density will be in the up layer and will flow together with the up pulp flow while material with bigger density will be in the down layer and will discharged from the down discharging port as jigging concentrate.

Advantages

- High capacity of jig plant

- High concentration ratio and high recovery of jig plant

- The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

- Saving water 30-40% than ordinary jig of jig plant

- The pulsation speed very easy adjusted by regulator

- Suitable for roughing and desliming

Daliuhang mining 1000t/d gold ore dressing plant

Parameters

| Jig | ||||||||||

Model | Jigging chamber shape | Jigging chamber area(㎡) | stroke(mm) | jig frequency(c.p.m) | Feed particle(mm) | supplementary water | handling capacity(t/h) | Power(kw) | Weight(kg) | |

water yield(t/h) | pressure(Mpa) | |||||||||

JT0.57-1 | trapezoid | 0.57 | 0-17 | 80-160 | <10 | 2~5 | >0.1 | 1~2.5 | 1.5 | 610 |

JT1-1 | trapezoid | 1.04 | 0-21 | 2~4 | 2.2 | 900 | ||||

JT1.5-2 | rectangle | 1.5 | 0-25 | 3~6 | 3 | 1520 | ||||

JT1.5-2S | rectangle | 1.5 | 0-30 | 3~6 | 1.5×2 | 1780 | ||||

JT2-2 | rectangle | 2.28 | 0-17 | 4~8 | 3 | 1640 | ||||

JT2-2S | rectangle | 2.28 | 0-21 | 4~8 | 1.5×2 | 1900 | ||||

JT3-1 | rectangle | 3.3 | 0-20 | 60-120 | 5~10 | 5.5 | 3260 | |||

JT4-2S | rectangle | 4 | 0-25 | 6~12 | 4×2 | 4680 | ||||

JT5-2S | trapezoid | 4.48 | 0-35 | 7~15 | 5.5×2 | 4750 | ||||

JT1-2S | rectangle | 1 | 0-35 | 50-100 | <30 | 2~6 | 1.5×2 | 1180 | ||

JT3-2S | rectangle | 3 | 0-30 | 6~12 | 5.5×2 | 3720 | ||||

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский