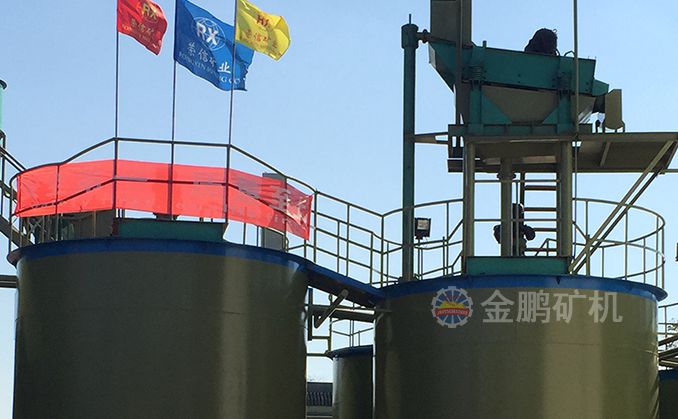

Pulp mixing tank

It is mainly used in the front of the flotation machine for the pulp mixing, the main function is to make the pulp and medicament can fully contact and blending, in preparation for the flotation operation, it can also be used in alumina production for desilication cutting, stripping tank, washing tank, also can be used in the chemical industry, building materials industry ,cyanide plant, sewage treatment plants and other industrial sectors.

Effective volume:0.25 to 11.2 m³

Structure

Applicable scope

mining, chemical industry, building materials, slurry mixing and cyanide plant, sewage treatment plant

Applicable material

density less than 30% and ore concentration is not more than 3.5% of the pulp ,and mixing of flotation reagents

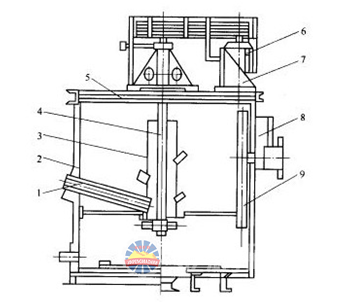

Product Structure

Mixing tank by the spindle assembly, shelves, tub, circular barrel, motor, motor base.The rotation of the impeller is passed by motor pulley, triangle and get the rotation of the impeller causes the pulp and medicament.

1.Feed tube 2.Tank body 3.Circular barrel 4.Transmission shaft 5.Crossbeam 6.Electromotor 7.Electromotor bracket

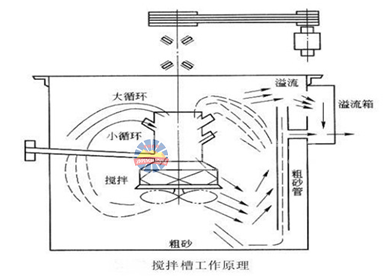

With the rotary of impeller,the pulp and chemical mixed together,the even suspension will be discharged by the overflow point.

Advantages

1.The impeller diameter is big, pulp and chemical mixing ability is strong

2.The impeller speed is big, pulp and chemical mixing ability is strong

3.Mixing ability enhancement, make pulp and chemical circulation ability also strengthened

Parameters

General Pulp mixing tank | ||||||

Model | Effective volume | Impeller speed | Impeller diameter | Electromotor | Weight | |

(m3) | (r.p.m) | (mm) | Model | Power(kw) | (kg) | |

BJ-500×500 | 0.074 | 525 | 240 | Y802-4 | 0.75 | 162 |

BJ-750×750 | 0.25 | 530 | 240 | Y100L-6 | 1.5 | 305 |

BJ-1000×1000 | 0.58 | 513 | 230 | Y90L-4 | 1.5 | 680 |

BJ-1250×1250 | 1.4 | 401 | 380 | Y100L1-4 | 2.2 | 1008 |

BJ-1500×1500 | 2.1 | 332 | 380 | Y132M1-6 | 4 | 1310 |

BJ-1600×1600 | 2.56 | 332 | 380 | Y132M2-6 | 5.5 | 1630 |

BJ-2000×2000 | 4.4 | 305 | 550 | Y160M-6 | 7.5 | 1900 |

BJ-2000×2500 | 5.97 | 285 | 630 | Y160M-6 | 7.5 | 2360 |

BJ-2500×2500 | 9.2 | 285 | 630 | Y160L-6 | 11 | 2766 |

BJ-3000×3000 | 17.5 | 200 | 800 | Y225M-8 | 22 | 4808 |

BJ-3500×3500 | 29.5 | 190 | 800 | Y225M-8 | 22 | 5580 |

BJ-3550×4000 | 35 | 194 | 850 | Y250M-8 | 30 | 5939 |

New type Pulp mixing tank | ||||||

Model | Effective volume | Impeller speed | Impeller diameter | Electromotor | Weight | |

(m3) | (r.p.m) | (mm) | Model | Power(kw) | (kg) | |

RJ-1000×1000 | 0.58 | 610 | 250 | Y90L-4 | 1.5 | 532 |

RJ-1250×1250 | 1.4 | 492 | 310 | Y100L1-4 | 2.2 | 700 |

RJ-1600×1600 | 2.67 | 332 | 400 | Y132M1-6 | 4 | 1170 |

RJ-2000×2000 | 5.46 | 305 | 500 | Y160M-6 | 7.5 | 2205 |

RJ-2500×2500 | 11.2 | 244 | 625 | Y160L-6 | 11 | 3500 |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский