Reagent mixing tank

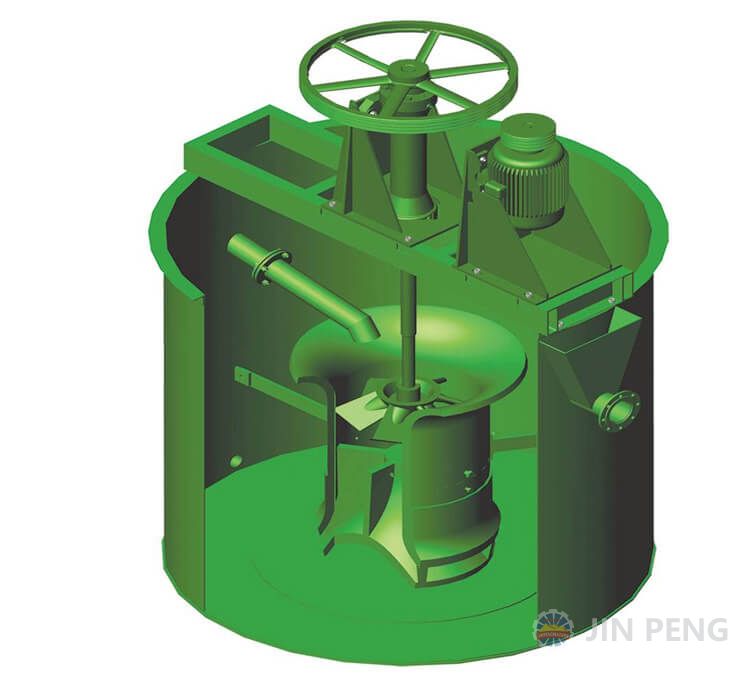

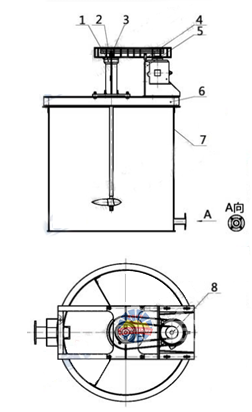

Reagent mixing tank is composed of vertical shaft, rack, tank, small pulley, motor, motor seat, safety hood. The rotation of the impeller is driven by a motor through a belt pulley and a triangular belt, and the rotation of the impeller that makes the chemical pulp mixing evenly.

Effective volume:0.0074-46m³

Structure

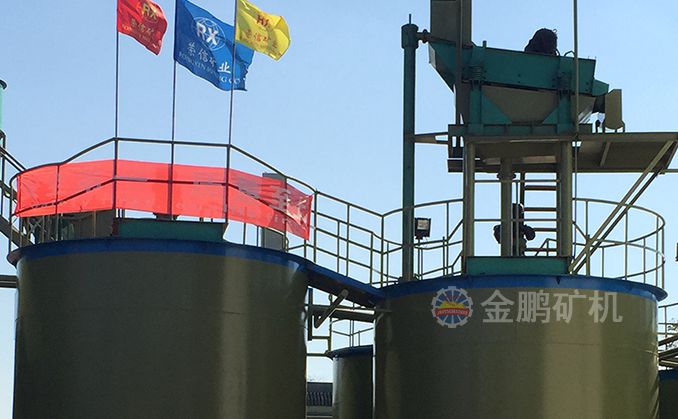

Scope of application

Reagent mixing tank for the preparation of a variety of Reagent before flotation operations

Applicable material

mixing pulp and flotation reagent concentration of not more than 30% strength and less than 3.5% of the mineral density

product construction

Reagent mixing tank composed of vertical shaft, rack, tank, small pulley, motor, motor seat, safety hood. The rotation of the impeller is driven by a motor through a belt pulley and a triangular belt, and the rotation of the impeller that makes the chemical pulp mixing evenly.

Working principle

The mixing method of flat bottom barrel shaped radial circulation spiral impeller is used for mixing operation. When stirred tank work motor drive V-belt device driving the rotation of the impeller, impeller rotational speed by reagent in mixing, mixing pulp and medicament in the next stage to make necessary preparations.

Advantages

Chemical mixing tank is a kind of application in the chemical mixing vessel equipment, the company made a great adjustment on the basis of the original, the effective volume in general 0.0074-46m3, has high production efficiency, energy saving, stable operation, convenient maintenance and other advantages, at the same time, we are still on the impeller stirred tank outsourcing corrosion resistant rubber according to corrosion agents, have very good protection effect, improve the service life of the tank, saving cost for customers.

Parameters

Reagent mixing tank | ||||||

Model | Effective volume(m³) | Impeller | Motor | Weight(KG) | ||

speed(r/min) | diameter(mm) | Model | Power(KW) | |||

BJW-500×500 | 0.074 | 525 | 240 | Y802-4 | 0.75 | 142 |

BJW-500×600 | 0.094 | 525 | 240 | Y802-4 | 0.75 | 210 |

BJW-750×750 | 0.25 | 530 | 240 | Y100L-6 | 1.5 | 280 |

BJW-1000×1000 | 0.58 | 513 | 230 | Y90L-4 | 1.5 | 420 |

BJW-1250×1250 | 1.4 | 401 | 380 | Y100L1-4 | 2.2 | 973 |

BJW-1500×1500 | 2.2 | 320 | 380 | Y132M1-6 | 4 | 1265 |

BJW- 1600×1600 | 2.56 | 332 | 380 | Y132M2-6 | 5.5 | 1530 |

BJW-2000×2000 | 5.46 | 233 | 550 | Y132M2-6 | 5.5 | 1850 |

BJW- 2500×2500 | 12.26 | 285 | 630 | Y160L-6 | 11 | 2681 |

BJW-3000×3000 | 17.5 | 200 | 800 | Y225S-8 | 18.5 | 4620 |

BJW- 3500×3500 | 29.5 | 190 | 800 | Y225M-8 | 22 | 5380 |

BJW- 4000×4000 | 46 | 200 | 1000 | Y250M-8 | 30 | 5380 |

New type Reagent mixing tank | ||||||

Model | Effective volume(m³) | Impeller | Motor | Weight(KG) | ||

speed(r/min) | diameter(mm) | Model | Power(KW) | |||

RJW——1000×1000 | 0.58 | 535 | 250 | Y90S-4 | 1.1 | 489 |

RJW——1250×1250 | 1.4 | 492 | 310 | Y100L1-4 | 2.2 | 610 |

RJW——1600×1600 | 2.67 | 332 | 400 | Y112M-6 | 2.2 | 1100 |

RJW——2000×2000 | 5.46 | 267 | 500 | Y132M1-6 | 4 | 2030 |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский