YA circular vibrating screen

This series vibrating screen with simple structure, and easy to maintenance, reliable to operation, and screen efficiency high. It can desliming, dehydration and removing medium operation for medium-grained material for mining, coal, electricity, construction and chemical materials. And installation of rubber screen is preferred for grading cokes material.

Scope of Application:Screening of fine grained material

Production capacity:1-1700t/h

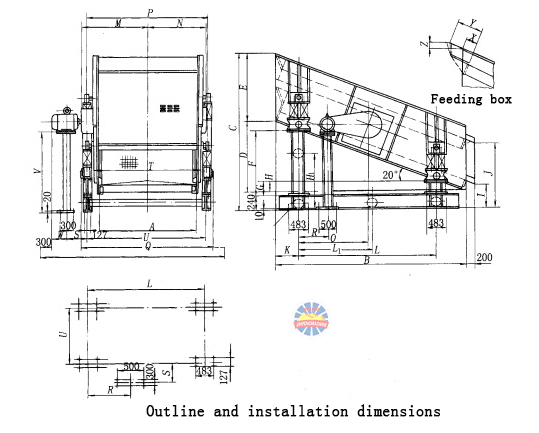

Structure

The motor spread to vibrator through the V belt, because the rotation of eccentric shaft causing vibration, making the screen deck do circular tracking movement, thereby make mineral rolling and vibrating on the surface of screen. The large on the surface of the screen, the size of the material less than screen pore will fall under the screen to achieve the purpose of screening.

Advantages

1. Improve your product purity - Eliminate oversized material from your powders and liquids

2. Increase your production - Double your throughput with half the size. These vibrating screens achieve a higher throughput per unit mesh area compared to conventional vibrating screens and can achieve throughput rates up to 60,000 kg/hour

3. Reduce your down-time - The Russell Compact Sieve can be easily stripped down and cleaned without tools

4. Eliminate dust and fumes - Enclosed screening means total containment

5. Fits into smaller spaces - These vibrating screens can fit easily into existing installations and areas of limited headroom

6. Lowers noise levels - A solid rubber suspension gives the machine a quiet operation - typically as low as 70dBA

7. Operating and cleaning is quick and easy, making this range of vibrating screens perfect for all processing industries. A wide range of sizes and options means the machine can be tailored to suit your exact needs.

Parameters

| YA Circular vibrating screen | ||||||||

| Model | sifter | Max particle(mm) | Production capacity(r/h) | Motor | weight(kg) | |||

| tier | area(㎡) | obliquity(°) | Model | power | ||||

| YA1224 | 1 | 2.9 | 20 | 100 | 60~200 | Y132S-4 | 5.5 | 4256 |

| 2YA1224 | 2 | 5160 | ||||||

| 3YA1224 | 3 | 5320 | ||||||

| YA1236 | 1 | 4.3 | 20 | 200 | 80~240 | Y160M-4 | 11 | 4905 |

| 2YA1236 | 2 | 5311 | ||||||

| YA1530 | 1 | 4.5 | 20 | 200 | 80~240 | Y160M-4 | 11 | 4675 |

| YA1536 | 1 | 5.4 | 20 | 200 | 100~350 | Y160M-4 | 11 | 5137 |

| 2YA1536 | 2 | 5.4 | 20 | 400 | 100~350 | Y160L-4 | 15 | 5624 |

| YAH1536 | 1 | 5.4 | 20 | 400 | 160~650 | Y160M-4 | 11 | 5625 |

| 2YAH1536 | 2 | 5.4 | 20 | 400 | 160~650 | Y160L-4 | 15 | 6045 |

| YA1542 | 1 | 6.5 | 20 | 200 | 110~385 | Y160L-4 | 15 | 5515 |

| 2YA1542 | 2 | 6098 | ||||||

| YA1548 | 1 | 7.2 | 20 | 200 | 120~420 | Y160L-4 | 15 | 5918 |

| 2YA1548 | 2 | 6321 | ||||||

| YAH1548 | 1 | 7.2 | 20 | 400 | 200~780 | Y160L-4 | 15 | 6842 |

| 2YAH1548 | 2 | 7404 | ||||||

| YA1836 | 1 | 6.5 | 20 | 200 | 140~220 | Y160M-4 | 11 | 5205 |

| 2YA1836 | 2 | Y160L-4 | 15 | 5946 | ||||

| YAH1836 | 1 | 6.5 | 20 | 400 | 220~900 | Y160M-4 | 11 | 5900 |

| 2YAH1836 | 2 | Y160L-4 | 15 | 6353 | ||||

| YA1842 | 1 | 7.6 | 20 | 200 | 140~490 | Y160L-4 | 15 | 5829 |

| 2YA1842 | 2 | 6437 | ||||||

| YAH1842 | 1 | 7.6 | 20 | 400 | 450~800 | Y160L-4 | 15 | 6352 |

| 2HAY1842 | 2 | 7037 | ||||||

| YA1848 | 1 | 8.6 | 20 | 200 | 150~525 | Y160L-4 | 15 | 6289 |

| 2YA1848 | 2 | 6624 | ||||||

| YAH1848 | 1 | 8.6 | 20 | 400 | 250~1000 | Y160L-4 | 15 | 7122 |

| 2YAH1848 | 2 | 7740 | ||||||

| YA2148 | 1 | 10 | 20 | 210 | 180~630 | Y180M-4 | 18.5 | 9033 |

| 2YA2148 | 2 | Y180L-4 | 22 | 10532 | ||||

| YAH2148 | 1 | 10 | 20 | 400 | 270~1200 | Y180M-4 | 18.5 | 10430 |

| 2YAH2148 | 2 | Y180L-4 | 22 | 11190 | ||||

| YA2160 | 1 | 12.6 | 20 | 200 | 230~800 | Y180M-4 | 18.5 | 9926 |

| 2YA2160 | 2 | Y180L-4 | 22 | 11249 | ||||

| YAH2160 | 1 | 12.6 | 20 | 400 | 350~1500 | Y200L-4 | 30 | 12490 |

| 2YAH2160 | 2 | 13858 | ||||||

| YA2448 | 1 | 11.5 | 20 | 200 | 200~700 | Y180M-4 | 18.5 | 9834 |

| YAH2448 | 1 | 11.5 | 20 | 400 | 310~1300 | Y200L-4 | 30 | 11830 |

| 2YAH2448 | 2 | 13012 | ||||||

| YA2460 | 1 | 14.4 | 20 | 200 | 260~780 | Y200L-4 | 30 | 12240 |

| 2YA2460 | 2 | 13583 | ||||||

| YAH2460 | 1 | 14.4 | 20 | 400 | 400~1700 | Y200L-4 | 30 | 13096 |

| 2YAH2460 | 2 | 14455 | ||||||

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский