Desorption electrowinning equipment

Desorption electrolysis system is applied to recover solid gold from carbons in the cyaniding process. It is equipped with liquid-level controlling system, temperature controlling system and automatic controlling system.

Scope of Application:High temperature and high pressure desorption electrolysis system

working principle

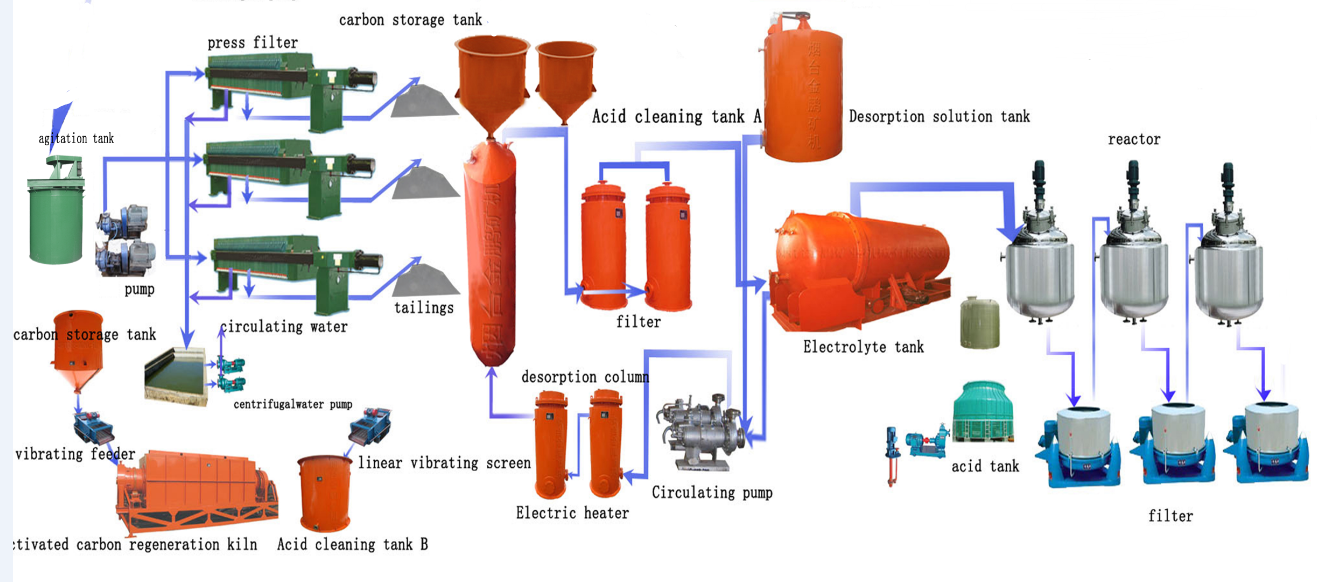

Desorption electrowinning equipment including: desorption column, electrolytic cell, electric heater, desorption fluid tank, filter, electric control cabinet, rectifier cabinet, circulating pump, activated carbon regeneration furnace, etc.

When the desorption system is added with anions which are more easily absorbed by activated carbons, Au(CN)2 is replaced by anion and the gold desorption is achieved. After the carbons loaded with gold are desorbed, pregnant solution is process via ionization. At last, solid gold is attained.

Advantages

High-efficiency: when the grade of loaded carbon reaches 3000g/t, the desorption rate can reach more than 96%, the barren carbon tenor with this equipment comparing with that of normal desorption electrowinning equipment will reduce to its one/ fourth.

Rapid: the temperature of desorption electrowinning can reach as high as 150°C(generally 30-55°C higher than in other kind system), and the working pressure of system can reach as high as 0.5 Mpa (generally 0.2-0.5 Mpa higher than in other kind system), so the desorption electrowinning is rapid with 12 hours typically(50%-60 % time shorted).

Low consumption: the same temperature for desorption, no need of heat-exchanging, working speed is rapid, power consumption is 1/2-1/4 of normal system.

Parameters

| Desorption electrowinning equipment | |||

| Model | Suitable size | Operating parameter | |

| Mine scale(t/d) | Crudes quality(g/t) | ||

| GKJD-200 | <150 | 2--8 | Temperature:150±2OC (Na0H)PH:≥13.5 Desorption pressure tank:0.5(Mpa) Electrolytic tank pressure:0.45(Mpa) |

| GKJD-300 | 150-300 | 2--8 | |

| GKJD-500 | 300-500 | 2--8 | |

| GKJD-700 | |||

| GKJD-1000 | 500-1000 | 2--8 | |

| GKJD-1500 | |||

| GKJD-2000 | 1000-2000 | 2--20 | |

| GKJD-2500 | |||

| GKJD-3000 | |||

| GKJD-3500 | 2000-3000 | 2--20 | |

| GKJD-4000 | |||

| GKJD-5000 | |||

| GKJD-8000 | 3000-5000 | 2--20 | |

| Electrical heater | ||||||

| Model | Temperature(℃) | Working medium | Electro-thermal power(KW) | Voltage(V) | Weight(kg) | Note |

| JDDR6 | 40 | NH4SCN | 2x3 | 380 | 80 | Resin electrowinning |

| JDDR18 | 98 | 1%NaOH+2%NaOH | 6x3 | 380 | ||

| JDDR24 | 98 | 1%NaOH+2%NaOH | 8x3 | 380 | 147 | |

| JDDR36 | 98 | 1%NaOH+2%NaOH | 6x6 | 380 | ||

| JDDR48 | 98 | 1%NaOH+2%NaOH | 8x6 | 380 | 138 | |

| Desorption column | ||||

| Model | Volume(m3) | Pressure(Pa) | Temperature(℃ ) | Working medium |

| φ300×2000 | 0.14 | Ordinary | 95~98 | NaOH2%+NaOH1% |

| φ450×2000 | 0.4 | Ordinary | 95~98 | |

| φ500×2500 | 0.49 | Ordinary | 95~98 | |

| φ500×3000 | 0.55 | Ordinary | 95~98 | |

| φ500×3720 | 0.7 | Ordinary | 95~98 | |

| φ518×3880 | 0.82 | Ordinary | 95~98 | |

| φ600×3000(2500) | 0.85(0.71) | Ordinary | 95~98 | |

| φ600×4300 | 1.2 | Ordinary | 95~98 | |

| φ700×3000 | 1.08 | Ordinary | 95~98 | |

| φ700×3800(2800) | 1.585(1.08) | Ordinary | 95~98 | |

| φ800×4000 | 2 | Ordinary | 95~98 | |

| φ900×4200 | 3 | Ordinary | 95~98 | |

| Heat exchanger | ||||

| Model | Specification | Heat exchange area(㎡) | Pressure(Pa) | Weight (kg) |

| JDRJ0413 | φ400×1300 | 6.25 | 0.35 | 325 |

| JDRJ0417 | φ400×1700 | 8 | 0.35 | 344 |

| JDRJ0418 | φ400×1800 | 9 | 0.35 | 490 |

| JDRJ0618 | φ600×1800 | 16 | 0.35 | 868 |

| JDRJ0830 | φ800×3000 | 38 | 0.35 | 1495 |

| Electrolytic cell | ||||||||

| Model | Effective volume(m3) | Cathode plate number | Anode plate number | Homopolar distance (mm) | Temperature(℃) | Voltage(V) | Electric current(A) | Note |

| DJC0.2 | 0.2 | 9 | 10 | 105 | 90~95 | 0~6 | 0~1000 | Resin Desorption |

| DJC0.4 | 0.4 | 7 | 8 | 105 | 90~95 | 0~6 | 0~1000 | |

| DJC0.6 | 0.6 | 11 | 12 | 105 | 90~95 | 0~6 | 0~1000 | |

| DJC0.8 | 0.8 | 15 | 16 | 105 | 90~95 | 0~6 | 0~1000 | |

| DJC1 | 1 | 20 | 21 | 105 | 90~95 | 0~6 | 0~1000 | |

| DJC0838 | 0.838 | 24 | 25 | 80 | 65±5 | 1.5~3 | 300~350 | |

| Storage tank of electrolytic solution | ||||

| Model | Specification | Filtration volume(m3) | Weight (kg) | Note |

| JDYC650 | φ400×1300 | 0.22 | 126 | rectangle |

| JDYC900 | φ900×900 | 0.57 | 229 | |

| JDYC1000 | φ1000×1200 | 0.94 | 252 | |

| JDYC1200 | φ1200×1200 | 1.36 | 308 | |

| JDYC1350 | φ1350×1400 | 2 | 368 | |

| JDYC1500 | φ1500×1500 | 2.65 | 558 | |

| JDYC2250 | φ2250×1500 | 5.96 | 951 | |

| JDYC2 | 2280×1188×888 | 2 | 490 | |

| Storage tank of Gold charcoal | |||

| Model | Specification | Thickness(mm) | Weight (kg) |

| JDCC600 | φ600×1050 | 5 | 104 |

| JDCC900 | φ900×1805 | 5 | 242 |

| JDCC1000 | φ1000×2005 | 5 | 334 |

| JDCC1200 | φ1200×2390 | 5 | 384 |

| Filter | ||||

| Model | Volume(m3) | Temperature(℃) | Pressure(Pa) | Weight (kg) |

| JDG600 | 2 | 135 | ≤0.5 | 349 |

(Tips: You can add this webpage as favourite, or find it by serach in Google with the keywords below: gold refinery plant and so on.)

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский