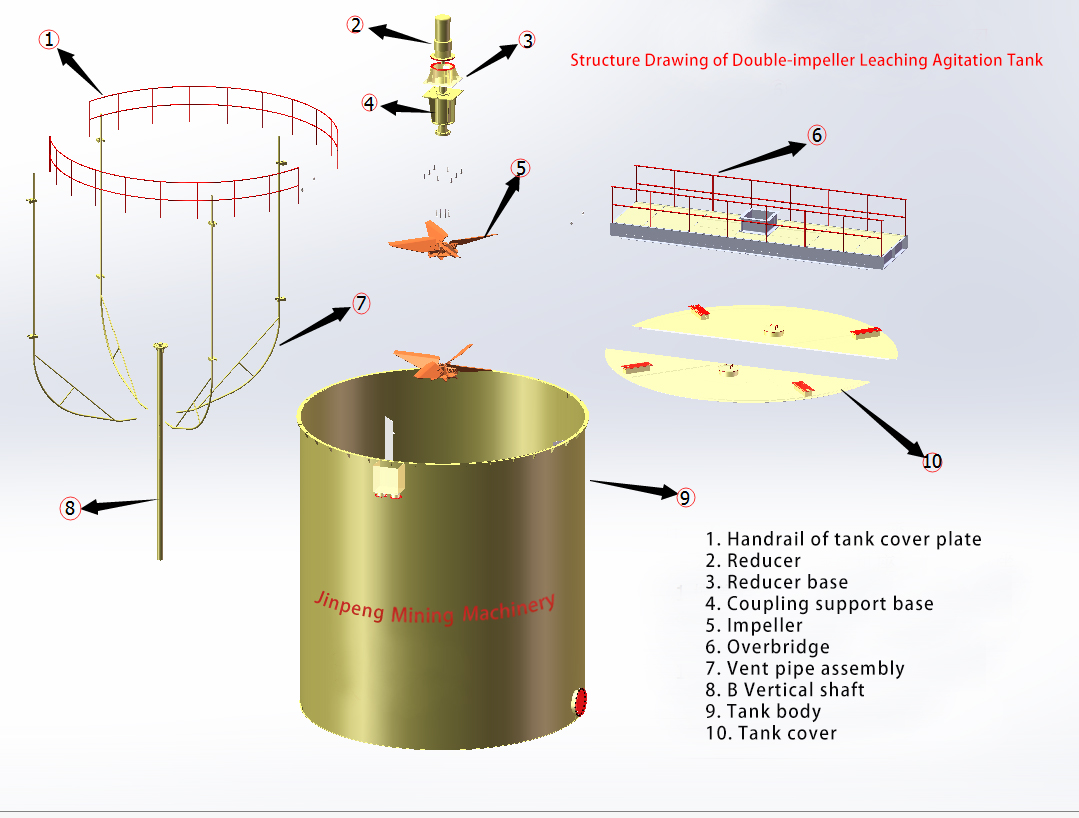

Double impeller leaching stirred tank

Compare double impeller leaching stirred tank with the ordinary mixing tank, it adopts the double impeller, the mixing of pulp can be more uniform, in terms of energy consumption, the more saving energy. the impeller use wrapping adhesive technology, long service life, moral give in to the gas use is for gas, air evenly.

Effective volume:6-1740m³

working principle

Scope of application

the proportion of small, low viscosity, sedimentation velocity is slow, ore particle size in 200 yard accounted for more than 90%, pulp density is less than 45% of gold leaching, adsorption and other mixed in.

product working principle

Pulp in double impeller and stirring under the action of the drag, the flow in the center from top to bottom, the diffusion of damping plate, on the lower end of the shaft into the air, and pulp are mixed and upward circulation, forming uniform suspension mixture.

Advantages

The characteristics of the double leaf leaching stirred tank:

1. Ventilation, is surrounded by air to the bottom of the tube or hollow shaft ventilation, make the air through the air tube or hollow shaft into the mixing tank, uniform gas dispersion, small air bubbles.

2. The is a new type of rubber impeller in large diameter, rotational speed is low, long service life.

3. Have very strict control on the stirring intensity, make the concentration of the mixing tank and fineness is consistent with the distribution.To improve the rate of pass in and out of cyanide and carbon adsorption rate.

I company for pneumatic system, air lift system, carbon carbon isolation system for the structure optimization and improvement.Ore flow smooth movement, pulp mixing, less power consumption, thereby reducing the wear of carbon.Compact structure, convenient maintenance.Development of maximum diameter of more than 10 m leaching tank specification, also continue to improve structure and performance.

Parameters

| Double impeller leaching stirred tank | |||||||||||

| Model | Tank specifications(mm) D×L | Effective volume(m³) | Impelle | Diameter | Planet-cycloid reducer | Tank weight(kg) | (kg) | ||||

| Speedr/min | Diameter(mm) | Feed tube(mm) | Discharge tube(mm) | Model | Speed ratio | Motor power(kw) | |||||

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2—Φ133×8 | 2—Φ133×8 | XLD2.2-4-29 | 29 | 2.2 | 2144 | |

| SJ2.5×3.15 | 2500×3150 | 13.14 | 935 | 2—Φ133×8 | 2—Φ133×8 | 2242 | 3095 | ||||

| SJ3.0×3.0 | 3000×3000 | 18 | 40.85 | 1130 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 35 | 4 | 2802 | 4161 |

| SJ3×3.15 | 3000×3150 | 18.93 | 43 | 1130 | 2—Φ150 | 2—Φ150 | 3331 | 4323 | |||

| SJ3.15×3.55 | 3150×3550 | 24 | 43 | 1260 | 2—Φ150 | 2—Φ150 | 3391 | 4583 | |||

| SJ3.5×3.5 | 3500×3500 | 30 | 52 | 1310 | 2—Φ150 | 2—Φ150 | XLD5.5-5-29 | 29 | 5.5 | 4286 | 5025 |

| SJ3.5×4.0 | 3500×4000 | 32.7 | 41 | 1310 | 2—Φ150 | 2—Φ150 | 4631 | 5429 | |||

| SJ3.55×4.0 | 3550×4000 | 33.6 | 43 | 1310 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 35 | 4 | 4860 | 5825 |

| SJ3.7×4.2 | 3700×4200 | 38.4 | 42 | 1310 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 43 | 4 | 5058 | 6153 |

| SJ4.0×4.0 | 4000×4000 | 38 | 35 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 6056 | 7450 |

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 6106 | 7569 |

| SJ4.5×5.0 | 4500×5000 | 71.57 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 7506 | 10864 | |

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 2—Φ159×8 | 2—Φ159×8 | XLD11-8-47 | 47 | 11 | 10483 | 14291 |

| SJ5.5×6.0 | 5500×6000 | 112 | 2100 | 2—Φ159×8 | 2—Φ159×8 | 47 | 11 | 14209 | 18745 | ||

| Φ6×6.5 | 6000×6500 | 170 | 24.9 | 2300 | 2—Φ168×8 | 2—Φ168×8 | XLD18.5-9-35 | 31.5 | 18.5 | 16164 | 21006 |

| Φ6.5×7 | 6500×7000 | 215 | 23 | 2400 | 2—Φ168×8 | 2—Φ168×8 | XLD18.5-9-43 | 43 | 22 | 17190 | 25567 |

| Φ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 2—Φ168×8 | 2—Φ168×8 | XLD22-10-47 | 47 | 22 | 22091 | 30486 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 21 | 2900 | 2—Φ168×8 | 2—Φ168×8 | XLD22-10-47 | 47 | 22 | 26958 | 34365 |

| SJ8.0×8.5 | 8000×8500 | 342 | 16.4 | 3200 | 2—Φ219×8 | 2—Φ219×8 | Y250M-8 | 30 | 33489 | 42468 | |

| Φ8.5×9 | 8500×9000 | 395 | 18.5 | 3300 | 2—Φ219×8 | 2—Φ219×8 | Y250M-8 | 30 | 36696 | 46623 | |

| Φ9.5×10 | 9500×10000 | 648 | 16.6 | 3750 | 2—Φ273×8 | 2—Φ273×8 | Y280S-8 | 37 | 46261 | 59786 | |

| Φ10.5×11 | 10500×11000 | 900 | 13.28 | 4400 | 2—Φ325×8 | 2—Φ325×8 | Y315S-8 | 55 | 56888 | 72647 | |

| Φ11.5×12 | 11500×12000 | 1190 | 12.1 | 4600 | 2—Φ325×8 | 2—Φ325×8 | Y315M-8 | 75 | 67669 | 95669 | |

| Φ12×13 | 12000×13000 | 1414 | 13.4 | 4600 | 2—Φ377×8 | 2—Φ377×8 | Y315L1-8 | 90 | 88418 | 120635 | |

| Φ13×14 | 13000×14000 | 1740 | 10.7 | 5200 | 2—Φ377×8 | 2—Φ377×8 | JR125-8 | 110 | 113669 | 148666 | |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский