GX Fixed screw conveyor

Screw conveyor (hereinafter referred to as screw machine) is a continuous conveyor equipment without traction components around the shaft. It uses a rotating helical blade over material movement in the chassis so as to achieve the purpose of conveying materials.

Production capacity:4.5-139 t/h

Scope of Application:Chemical industry, building materials, food and other departments

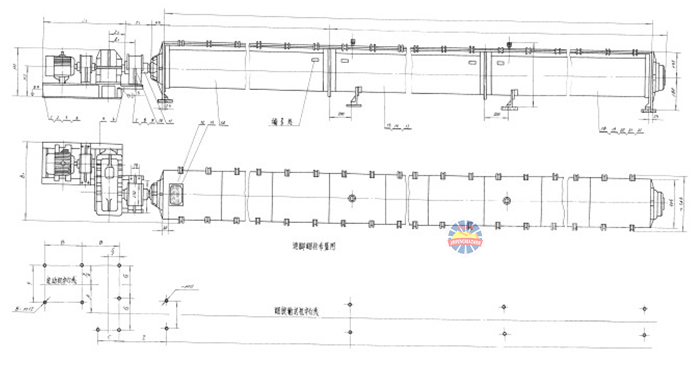

Structure

Screw machine needs feeding evenly, otherwise easily lead to sieve accumulation and result in machine overload, its hanging bearings’, bearing wear faster, which often requires to be repaired.

This series of screw machine diameter is from 150 mm to 600 mm, seven kinds of specifications available. Length from 5 meters to 70 meters, half a meter at intervals as a file, you can freely automatically select.GX screw conveyor is a fixed screw machine with horizontal or inclined less than 20 °, it could only transportation of materials in one-way direction, but also in the course of transmission should not be at the same time with certain process operation.Such as mixer, etc.

Advantages

Due to its simple mechanism, small foot print, manufacturing and installation is relatively easy. Screw machine is divided into drives, a number of the middle section, head section and tail section.

The lid on the Screw body better able to seal, in the course of transmission, the transported materials can be isolated from the outside.Above is the screw machine advantage.

In the course of transmission, it is necessary to overcome materials and spiral casing friction, large unit power consumption .As the result of the spiral effect, the material is easy to crush; meanwhile, the spiral and the body have some wear and tear, which is a screw machine defect.

Above-mentioned there is advantages and disadvantages to screw machine, limiting the use of screw machine, which is in a variety of industrial production, transport all sorts of powder, granular, and the small block of material. Such as

coal, flour, cement, sand and stones and other types of coal lump. Not easy to transport perishable, Viscous, easy caking materials, these materials will bond the helix in the transportation, together with it spinning but not moving forward or

in the hanging of bearing forming materials plug , so screw machine is almost not work.

Due to the use of materials rotation and impelling materials and small effective flow area of materials, hence not easy

to transport bulk materials .Because of screw machine large power consumption,Therefore, often used for low or

medium transmission capacity and transmission length of small (less than 70 meters and 50 meters below is the better).

Parameters

GX Fixed screw conveyor | |||||||||||

model | screw diameter(mm) | Magnesium powder conveying capacity(t/h) | cement conveying capacity(t/h) | sodium carbonate conveying capacity(t/h) | width×height (mm) | Inlet shortest arrangement(mm) | Inlet square opening size (mm) | Inlet height (mm) | outlet square opening size (mm) | outlet height(mm) | |

GX15 | 150 | 4.5 | 4.1 | 3 | 272×314 | 190 | 170 | 75 | 176 | 135 | |

GX20 | 200 | 8.5 | 7.9 | 6.7 | 342×384 | 220 | 220 | 100 | 226 | 165 | |

GX25 | 250 | 16.5 | 15.6 | 10.7 | 392×464 | 270 | 270 | 120 | 276 | 195 | |

GX30 | 300 | 23.3 | 21.2 | 18 | 468×555 | 300 | 320 | 140 | 328 | 225 | |

GX40 | 400 | 54 | 51 | 35.5 | 572×685 | 350 | 420 | 160 | 428 | 280 | |

GX50 | 500 | 89 | 85 | 70 | 706×823 | 450 | 528 | 160 | 536 | 340 | |

GX60 | 600 | 139 | 134 | 97 | 806×973 | 550 | 628 | 180 | 636 | 430 | |

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский