SF Flotation machine

Flotation cell is widely used for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimed.

Applicable material:non-ferrous metals, ferrous metals and non-metallic mineral sorting

Production capacity:0.2-24 m³/min

Structure

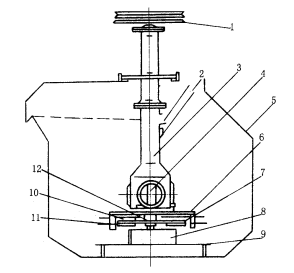

SF Flotation machine

1. belt wheel 2. aspirating tube 3. center cylinder 4. principal axis 5. cell body 6. cover board 7. Impeller 8. honeycomb duct 9. false bottom 10. the upper blade 11.the lowerblade 12. impeller disk

When the flotation machine works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

Advantages

1.Large air-absorption capacity and low power consumption

2.Long service life of vulnerable parts

3.Suitable for flotation of large particle size materials

4.Can compose a joint flotation unit with JJF flotation cell

Parameters

SF Flotation machine | |||||||

Model | Effective volume(m³) | Production capacity (m³/min) | Impeller diameter(mm) | Impeller revolutions(r/min) | Motor power(kw) | 2 tanks weight | |

Agitator | Scraper blade | ||||||

SF-0.37 | 0.37 | 0.2-0.4 | 300 | 352-442 | 1.5 | 0.55 | 940 |

SF-0.7 | 0.7 | 0.3-1.0 | 350 | 336 | 3 | 1.1 | 1940 |

SF-1.2 | 1.2 | 0.6-1.2 | 450 | 312 | 5.5 | 1.1 | 2800 |

SF-2.8 | 2.8 | 1.5-3.5 | 550 | 280 | 11 | 1.5 | 4240 |

SF-4 | 4 | 2--4 | 650 | 235 | 15 | 1.5 | 5200 |

SF-6 | 6 | 3--6 | 760 | 191 | 30 | 2.2 | 6000 |

SF-8 | 8 | 4--8 | 760 | 191 | 30 | 1.5 | 8584 |

SF-16 | 16 | 5.0-16 | 850 | 169-193 | 45 | 1.5 | 14830 |

SF-20 | 20 | 5.0-20 | 730 | 186 | 30X2 | 1.5 | 19646 |

BF Flotation machine | |||||||||

Model | Effective volume(m³) | size(mm) | Impeller diameter(mm) | Impeller rotational speed(m/s) | Entrained-air volume (m³/㎡.min) | Motor | Production capacity(m³/min) | Single tank weight | |

Model | Power(kw) | ||||||||

BF-0.15 | 0.15 | 550×550×600 | 200 | 6 | 0.9-1.05 | Y112M-6 | 2.2 | 0.06-0.16 | 270 |

BF-0.25 | 0.25 | 650×600×700 | 250 | Y100L-6 | 1.5 | 0.12-0.28 | 370 | ||

BF-0.37 | 0.37 | 740×740×750 | 286 | 7.2 | Y90L-4 | 0.2-0.4 | 470 | ||

BF-0.65 | 0.65 | 850×950×900 | 300 | 7.35 | 0.9-1.10 | Y132S-6 | 3 | 0.3-0.7 | 932 |

BF-1.2 | 1.2 | 1050×1150×1100 | 450 | 7.02 | Y132M2-6 Y132M1-6 | 5.5/4 | 0.6-1.2 | 1370 | |

BF-2.0 | 2 | 1400×1450×1120 | 500 | 7.5 | Y160M-6 | 7.5 | 1.0-2.0 | 1750 | |

BF-2.8 | 2.8 | 1650×1650×1150 | 550 | 8.06 | Y180L-8 | 11 | 1.4-3.0 | 2130 | |

BF-4.0 | 4 | 1900×2000×1200 | 650 | 8 | Y200L-8 | 15 | 2.4-4.0 | 2585 | |

BF-6.0 | 6 | 2200×2350×1300 | 700 | 7.5 | Y225S-8 | 18.5 | 3.0-6.0 | 3300 | |

BF-8.0 | 8 | 2250×2850×1400 | 760 | Y225M-8 | 22 | 4.0-8.0 | 4130 | ||

BF-10 | 10 | 2250×2850×1700 | 7.52 | 5.0-10 | 4500 | ||||

BF-16 | 16 | 2850×3800×1700 | 850 | 8.7 | Y280S-8 Y280M-8 | 37/45 | 8.0-16 | 8320 | |

| BF-20 | 20 | 2850×3800×2000 | 10.0-20 | 8670 | |||||

| BF-24 | 24 | 3150×4150×2000 | 920 | Y280M-8 | 45 | 12.0-24 | 8970 | ||

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский