XJB Rod type Flotation machine

Flotation cell is widely used for roughing, concentrating and reverse flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic minerals.

Applicable material:Big density, coarse ore particles, especially for lead, zinc, copper, molybdenum, sulfur, and silicon sand don't chosen

Production capacity:Flotation cell is widely used for roughing, concentrating and reverse flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic minerals.

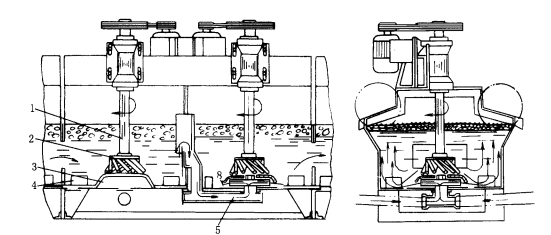

Structure

XJB Rod type Flotation machine

1. principal axis 2.Inclined rod wheel 3. lug boss 4. current regulator 5. Guide slurry pipe 6. cover board 7. Absorption of paddle wheel 8. chassis

When the flotation machine works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

Features

Structure feature

Impeller is consisted of a disc and 12 bevel cone bars. The rotating speed of bevel cone bar gets faster and faster while downing and agitation force gets stronger accordingly.

There is a convex bench and an arc-shaped steady flow plate. The convex bench works as the guide groove, which makes the mixture of air and slurry rush to the bottom of tank. And then with the steady flow plate the mixture spreads in the tank uniformly, moving in the shape of W.

Shallow tank with a depth of 2/3 of that of other flotation cell

Capacity feature

Strong agitation force; nice moving trace of slurry; suitable for the selection of coarse ore with bigger gravity and high sedimentation rate

Uniform mixing of slurry, air and sedimentation rate

Rapid flotation speed

Easy to restart after stopping

Special hint

Mechanical agitation; self-air suction; divided into suction cell (automatic suction slurry) and direct flow cell (non-automatic slurry suction).

Divided into single side scraping and double sides scraping

Parameters

XJB Rod type Flotation machine | |||||||||

Model | tank type | Effective volume | Production capacity | Impeller diameter | Impeller speed | Motor power(kw) | 4 tanks weight | ||

(m3) | (m3/min) | (mm) | (r.p.m) | Agitator | Scraper blade | (kg) | |||

XJB-1 | Suction tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5344 | |

XJB-1 | Cocurrent tank | 410 | 410 | 4 | 0.8 | ||||

XJB-1D | Suction tank | 400 | 440 | 5.5 | 1.5 | 5479 | |||

XJB-1D | Cocurrent tank | 410 | 410 | 4 | 0.8 | ||||

XJB-2 | Suction tank | 2 | 1.5-4 | 450 | 360 | 15 | 1.1 | 9071 | |

XJB-2 | Cocurrent tank | 540 | 11 | ||||||

XJB-2D | Suction tank | 450 | 15 | 9320 | |||||

XJB-2D | Cocurrent tank | 540 | 11 | ||||||

XJB-4 | Suction tank | 4 | 2.0-4 | 700 | 280 | 18.5 | 16325 | ||

XJB-4 | Cocurrent tank | 510 | |||||||

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский