Disc feeder

This product is applicable to the ore processing plant, smelting plant, cement plant, sands, machine casting workshop, usually hanging on the steel structure, installed in the bottom hopper for continuous feeding.

Max particle:20-80mm

Production capacity:0~88.4t/h

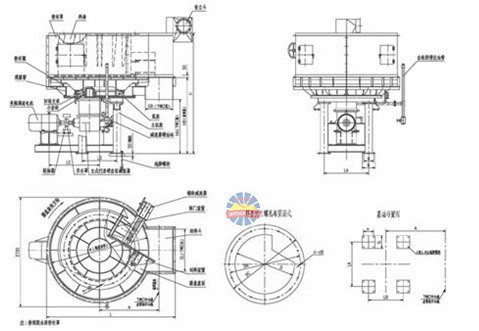

Structure

Applicable materials

slag, clinker, gypsum, limestone, clay, slag powder, granular or small block material, etc

product operating principle

Material from the hopper into the cylinder, materials along the material feeding cylinder are stored on the disc depending on itself weight. Using adjusting bolts to adjust the clearance between the sleeve and the disc then to control the corner of the nature of the material on the disc.Disc rotates, the material was evenly scraping by the knife on the disc to discharge the outside of the disc, such as the rotating disk, the material will catch by uniform discharge knife scraping into the materials hopper.Disk is continuously operating to completes the uniform feeding operations.Adjust the clearance between the unloading knife and disc, can also control the feeding capacity. When feeder is working, motor through the pulley drives the disk installed on the worm gear reducer.

Advantages

1. Stable operation and easy to operate;

2. The broad scope, efficient;

3. The big bearing capacity, smooth operation;

4. simple structure, uniform feeding, reliable usage, if adjust the distance between adjusting sleeve and disc, can achieve the purpose of regulating feeding capacity.

Parameters

Disc feeder | |||||||

Model | Disc diameter(mm) | Disc speed(r/min) | feeding capacity(t/h) | Electromotor mode | Electromotor power(kW) | Weight(kg) | |

Closed Hanging type | YG300 | 300 | 10 | 0 〜1.8 | Y80L-4 | 0.55 | 115 |

YG400 | 400 | 10.7 | 0 〜2.6 | Y90L-6 | 1.1 | 120 | |

YG500 | 500 | 0 〜3.3 | Y90L-6 | 1.1 | 124 | ||

YG600 | 600 | 10 | 0 〜5.0 | Y90L-6 | 1.1 | 130 | |

YG800 | 800 | 9 | 0 〜8.0 | Y90L-6 | 1.1 | 195 | |

YG1000 | 1000 | 9 | 0〜12 | Y90L-4 | 1.5 | 263 | |

YG1500 | 1500 | 7 | 0〜22 | Y132M2-6 | 5.5 | 755 | |

YG2000 | 2000 | 5 | 0〜80 | Y160L-6 | 11 | 2517 | |

Opened Hanging type | DK600 | 600 | 7.53 | 1. 8〜3.9 | Y90L-6 | 1.1 | 410 |

DK800 | 800 | 7.53 | 3. 5 〜7.6 | 600 | |||

DK1000 | 1000 | 7.5 | 1.8〜16.7 | Y100L-6 | 1.5 | 725 | |

DK1300 | 1300 | 6.5 | 4. 3 〜27.9 | Y132S-6 | 3 | 846 | |

DK1600 | 1600 | 6 | 7.03 〜48.6 | Y132M1-6 | 4 | 1980 | |

DK1800 | 1800 | 5 | 9.26 〜60 | Y132M2-6 | 5.5 | 3070 | |

DK2000 | 2000 | 13.6 〜88.4 | Y132M2-6 | 3260 | |||

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский