Swaying feeder

This machine is an auxiliary device for the transport machinery, suitable for concentrator, smelters, cement plants, placer, machinery casting workshop and other departments in the suspension steel structure, installed in the lower part of the hopper made by continuous feeding. Uniform, quantitative and continuous ores can be supplied of bulk, granular or powdery materials.

Max particle:25-50mm

Feeding capacity:4.5~25t/h

Structure

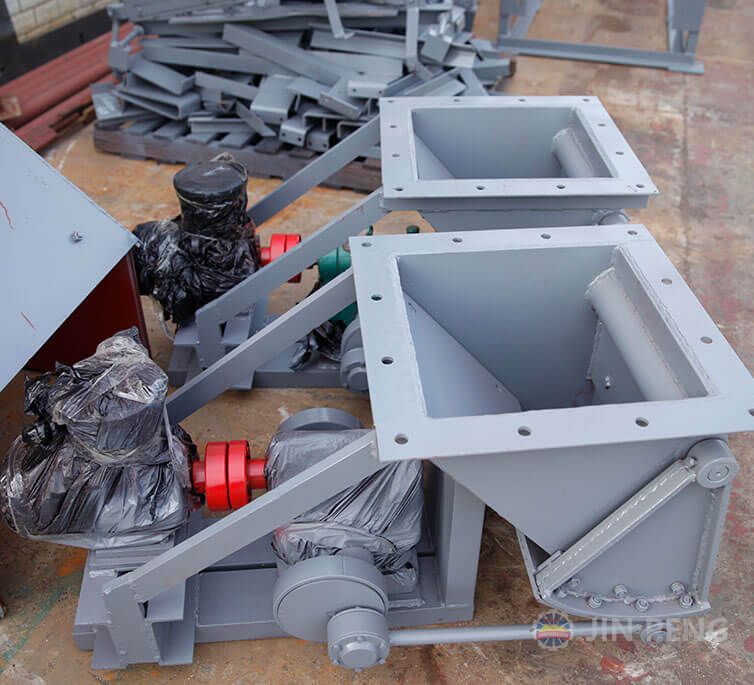

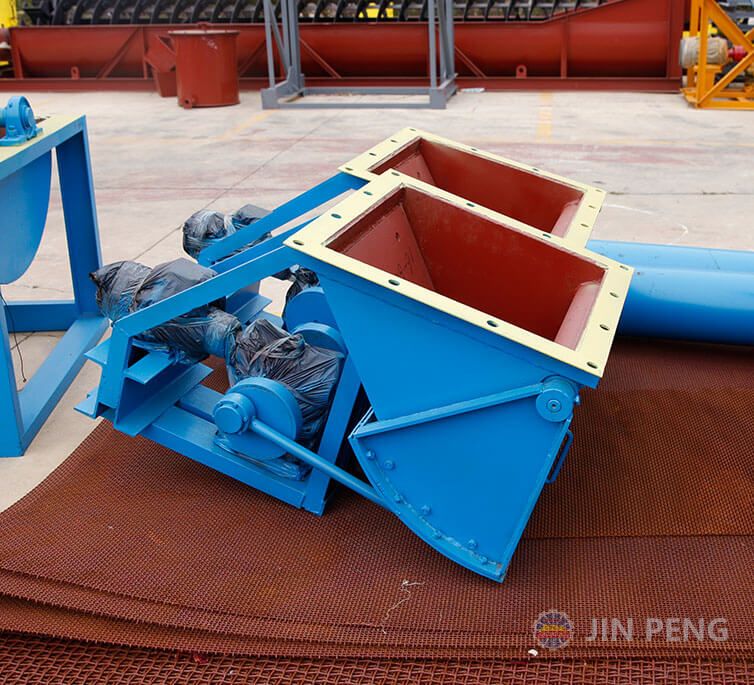

Product Structure

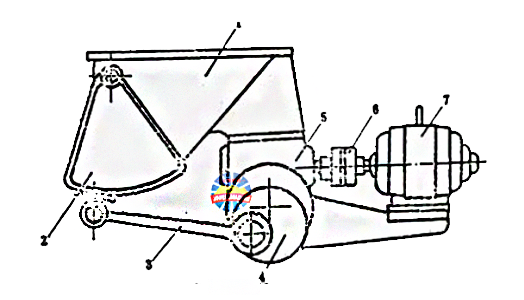

1.valve body 2.Valve door 3.Connecting rod 4.Eccentric wheel 5.Reduction gearbox 6.Coupling 7.Electromotor

Product working principle

This machine uses the principle of eccentric wheel mechanism, so that the jaw plate do reciprocating movement.The material will be evenly distributed. The driving force of the utility model is that the eccentric wheel is driven by a motor through a turbine speed reducer, and then the circular motion is changed into reciprocating motion after the connecting rod, and the reciprocating motion of the jaw plate is driven. When the jaw plate clockwise swing on it making the accumulation of material due to friction and driven with movement, to fill the body outwards by the space formed from the storage hopper in the pouring down part of the new material, when the jaw does anti clockwise movement, because the barrier material within the material cannot follow the jaw plate into the body inside, so it is in its under the push by the feeding tube or conveyor feeding funnel,all in all short periodic oscillation can make the jaw plate continuous material feeding.

Advantages

It is installed in the bottom of the storage tank or funnel to transport the particle size does not exceed 50mm, dry and not easy to agglomerate material, such as ore, etc.. However, it is not suitable for conveying powder material, which can easily lead to clogging, but also can cause the powder to fly and influence the cleaning of the workplace.

Parameters

Pendulum feeder | ||||||||||

Model | Input Measure(mm) | Output Measure(mm) | eccentric throw(mm) | Frequency(r/min) | Max particle(mm) | Production capacity(t/h) | Dynamo model | Dynamo power(kw) | Dynamo speed(r/min) | Weight(kg) |

BG250×250 | 250×250 | 250×30-125 | 0-90 | 46 | 25 | 4.5 | Y80L-4 | 0.55 | 1390 | 130 |

BG300×300 | 300×300 | 300×30-125 | 0-90 | 46 | 30 | 6.5 | Y802-4 | 0.75 | 1390 | 150 |

BG400×400 | 400×400 | 400×50-130 | 0-170 | 45.5 | 35 | 12 | Y90S-4 | 1.1 | 1410 | 300 |

BG600×600 | 600×600 | 600×50-150 | 0-200 | 45.8 | 50 | 25 | Y190L-4 | 1.5 | 1410 | 450 |

Related case

Sudan 500t/d CIL plant

Browse other product

You can share this to your friends

Please leave a message and we'll get back to you.

Español

Español русский

русский